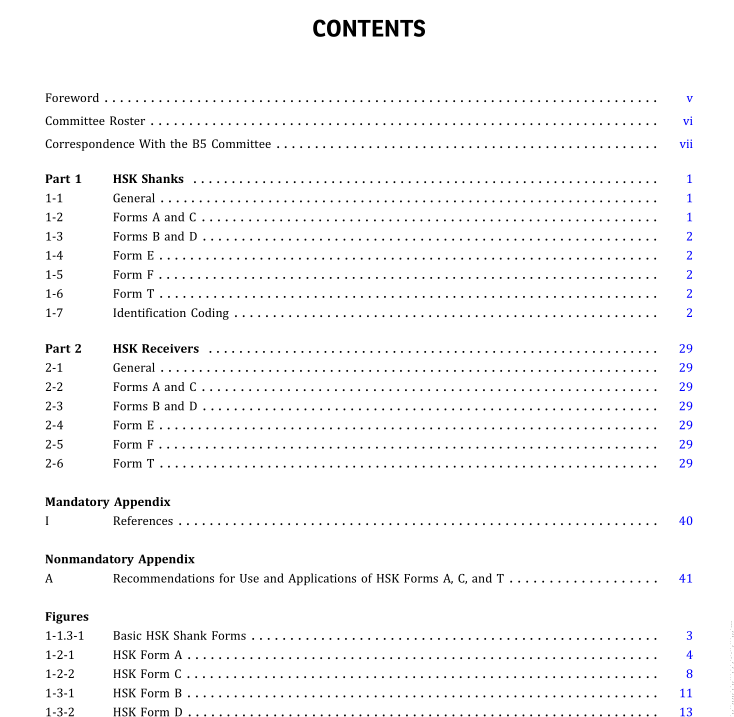

ASME B5.62M pdf download

ASME B5.62M pdf download Hollow Taper Tooling With Flange-Face Contact

1-1 GENERAL

1-1. Scope

This Standard covers basic toolholder shanks with ahollow 1/9.98 taper,and simultaneous contact faceand taper mating surfaces that are applicable to arange of machine tool applications. Hollow taper shank(HSK shank) Forms A, B, CD,E, Fand T with nominalflange diameters of 25 mm to 160 mm are covered bythis Standard.

1-l.2 Interchangeability

Machine toolinterfaces conforming to this Standard areinterchangeable with machine toolinterfaces conformingto DIN 69893-1:2003,DIN 69893-2:2003,DIN 698935:2004,DIN 69893-6:2003,S012164-1:2001.1S012164-2:2001,1S012164-3:2008andIS012164-4:2008

1-1.3 Forms

The HSK machine toolinterfaces as manufactured in theseven basicshankforms (see Figure 1-1.3-1),andas customized by selection of several optional features, arcsuitable for use in a wide range of machine tool applications. The seven basic shank forms are as follows:

(a) Form A Form A is the preferred design for use onmachine tools with automatic tool changers. Keyways arelocated at the small end of the tool taper. Form A includesprovision for through-tool coolant and manual toochange. See Figure 1-1.3-1,illustration (a).

(b) Form B. Like Form A, Form B is for use on machinetools with automatic tool changers, but it has a reducedtaper compared to Form A. Keyways are located on theflange. Form B includes provision for through-flangccoolant and manual tool change.See Figure 1-1.3-1, illustration (b).

(c) Form C Form C is similar to Form A but is intendedfor use on machine tools requiring manual tool changeTools with Form C shanks are typically used on transfellines, or as part of a modular tooling system. See Figure 11.3-1, illustration (c).

(d) Form D Form D is similar to Form B but is intendedforuse on machinetools requiring manual tool change.SeeFigure 1-1.3-1 illustration (d).

(e) Form E. Form E is similar to Form A, but it does nothave keyways or orientation features. Form E is intendedfor high-speed machining. See Figure 1-1.3-1, illustration(e

(f) Form F Form Fis similar to Form E but has a reducedtaper size. Form F is intended for high-speed machiningSee Figure 1-1.3-1, illustration (f).

(g) Form T Form T is similar to Form A but has modifications to accommodate use with stationary tools. SeeFigure 1-1.3-1, illustration (g).

l-l.4 Definitions

balance: the condition in which the mass centerline androtational centerline of a rotor are coincident.

clamp set: a mechanical device for securing a shank in thereceiver.

data chip: a radio-frequency identification device.

drive key: a feature ofa machine toolintended to orientthetoolholder in the receiver and assist in delivery of thedriving torque from the spindle nose to the tool.

keyway: the part of a machine tool that receives the drivekey.

receiver: the spindle or nonrotating socket of a machine.shank: a unit that fits directly into the spindle or nonro-tating socket of a machine.

spindle: component assembly of the machine tool, thefunction of which is to accept the basic toolholder shankspindle nose: that part of a spindle into which the shank isaccepted.

1-1.5 Figure Interpretation

The Part 1 figures are illustrated and labeled in accor-dance with ASME Y14.5.

1-2 FORMS A AND C

Form A includes provisions for automatic tool change, adata chip, an orientation notch, an access hole for manualclampingdrive keyways, and through-spindle coolantsupply via coolant tube. Form C is intended for manualtool change and includes an access hole for manualclampingdrive keyways, and through-spindle coolantsupply.