ASME B89.1.7 pdf download

ASME B89.1.7 pdf download Performance Standard for Steel Measuring Tapes

4.6.1 Graduation Quality. When the graduations are lines, they shall be visually straight, perpendicular to the axis of the measuring tape, and all of the same thickness. The thickness of each line shall be constant throughout its length. The lines shall be such that they form a distinct and clear graduation and that their thickness does not cause inaccuracy of measurement. Certain sections of the measuring tape, especially towards the ends, may be subdivided into submultiples of the graduation interval adopted for the whole mea- sure. In that case, the thickness of the lines may be less in the areas of reduced graduation intervals than in the rest of the measuring tape.

4.6.2 Arrangement. The measuring tape shall be divided by graduations of units consistent with the SI system or U.S. Customary system. The SI units shall be in meters, centimeters, millimeters, and multiples or subdivisions thereof. The U.S. Customary units shall be in feet, inches, and multiples or subdivisions thereof, to include decimal or fractional divisions.

4.6.3 Length of Graduations. In general, as the sub- division of length becomes smaller, the subdivisions should be indicated by using graduations of shorter length. However, in no case should the length ofgradua- tions be less than 0.7 mm or 0.03 in. 4.6.4 Width. The graduation marks shall not be wider than 50% ofthe distance between two consecutive minor graduations.

4.7 Additional Markings All markings, other than graduations and numbering, should be so positioned and of such a size as not to interfere with the legibility of the steel measuring tapes.

4.8 Numbering

4.8.1 Size of Numbers. The size of the numbers denoting the major graduations shall be as large as prac- tical without reducing the legibility of the graduations. All digits shall be of a style that distinctly differentiates one number from another.

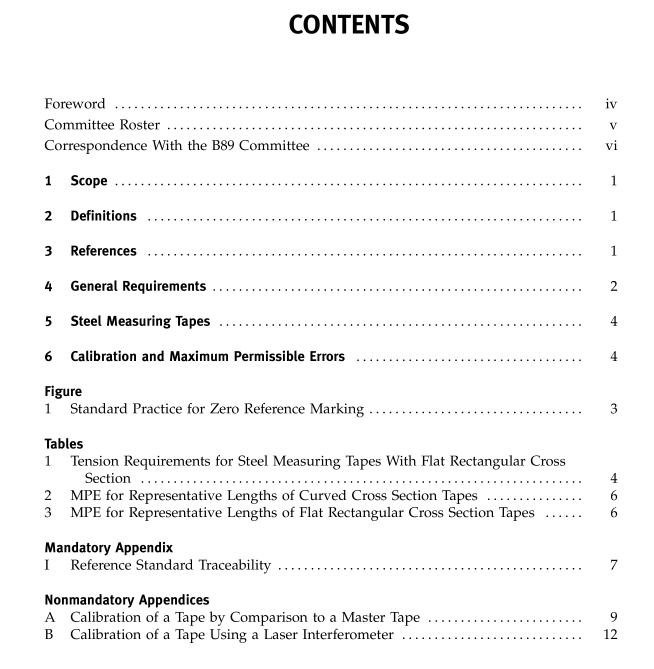

4.8.2 Zero Reference Mark. A tip, ring, hook, or end fitting may be included as a zero reference mark on the measuring tape. In this case, the numbering shall be positioned to accommodate the zero reference mark. Figure 1 illustrates the standard practice for the zero reference marking on various styles of tapes.

4.8.3 Distinguishing of Numbers. Numbers denot- ing each multiple or subdivision of a unit of length shall be distinguishable from each other by one or more of the following: size, color, orstyle. The numbers designat- ing the same multiple or subdivision shall be of the