ASME B89.4.19 pdf download

ASME B89.4.19 pdf download Performance Evaluation of Laser-Based Spherical Coordinate Measurement Systems

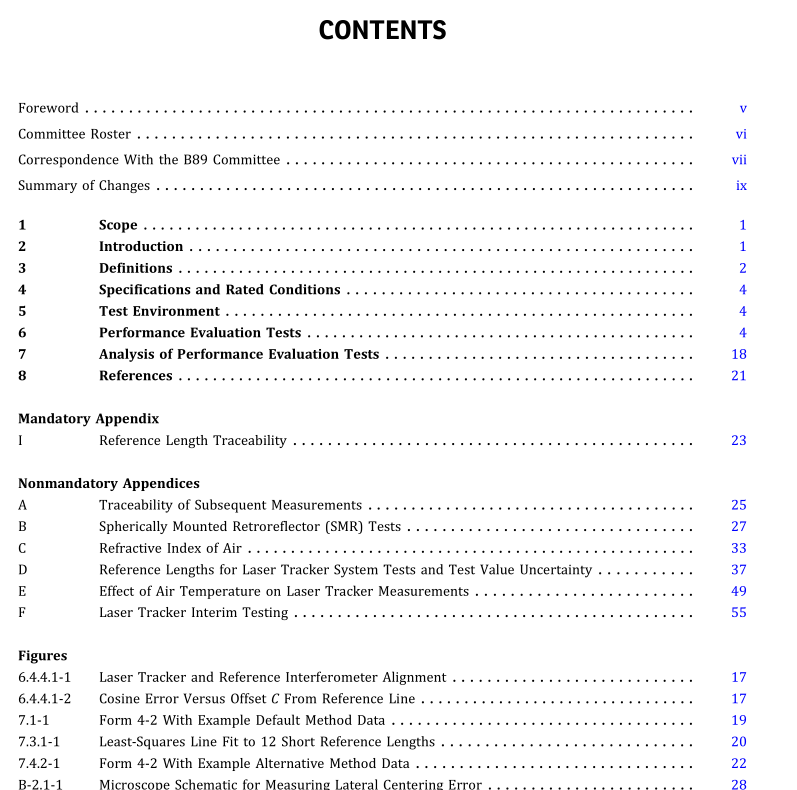

1 SCOPE

This Standard prescribes methods for the performance evaluation of laser-based spherical coordinate measurementsystems and provides a basis for performance comparisons among such systes. Definitions, environmental requirements, and test methods are included with emphasis on point-to-point length measurements.The specified test methodsare appropriate for the pertormance evaluation of a majority of laser-based spherical coordinate measurement systemsand are not intended to replace more complete tests that may be required for special applications.This Standard establishes requirements and methods for specifying and testing the performance of a class of sphericalcoordinate measurement systems called laser trackers A laser tracker is a system that directs the light from a rangemeasuring device to a retroreflecting target (called a retroreflector) by means ofa two-axis rotary steering mechanismwhile monitoring the angular position of these rotary axes, thereby forming a spherical coordinate metrology systemSuch a svstem may measure a static target, track and measure a moving target, or measure and perhaps track) somecombination of static and moving targets. This Standard can also be used to specify and verify the relevant performancctests of other spherical coordinate measurement systems that use cooperative targets, such as laser radar systemsThis Standard focuses specifcally on the use oflaser trackers as industrial measurement tools rather than on their usein surveying or geodesy.Specified tests are designed to evaluate the static point-to-point length measurement capabilitiesof these systems. The specified tests are not intended to evaluate the dynamic performance of the laser trackers. Addiional tests are included thatevaluate the range measurement capability of laser trackers equipped with absolute distancemeters(ADMs).The tests do notevaluate workpiece thermal compensation capability and are not sensitive to sphericallymounted retroreflector (SMR) imperfections

2INTRODUCTION

In addition to providing forthe performance evaluation oflaser trackers, this Standard facilitates performance compar.isons among different systems by unifying the terminology and the treatment of environmental factors. lt defines testmethods appropriate for evaluating the performance of a majority of laser trackers, but it is not intended to replace morecomplete tests that may be required for special applications.Systems that have passed the performance evaluation tests of this Standard are considered capable of producingtraceable point-to-point length measurements for the conditions required herein. Application of point-to-pointength measurements to a snecifc workniece or measurement task mav reguire additiona testing and analysis inorder to establish metrological traceability. This Standard provides technical guidance that may be useful in the calibration of laser-based spherical coordinate systems for point-to-point length measurements.The Appendices describe various factors that should be considered when using this Standard.(a) Mandatory Appendix I discusses metrological traceability, with particular focus on demonstrating traceability ofreference lengths used in laser tracker performance evaluation. Requirements for demonstrating metrolopical traceability are presented per ASME B897.5(b) Nonmandatory Appendix A discusses the traceability of laser tracker point-to-point length measurementsperformed subsequent to a system passing the performance evaluation tests described in this Standard.(c)Nonmandatory Appendix B describes tests and procedures for determining geometric errors in the construction ofSMRs so that the suitability of a particular SMR for laser tracker performance testing can be evaluated.(d)Nonmandatory Appendix C describes environmental factors that influence the refractive index oflight in air.Thesefactors affectthe wavelength oflight and should be carefully understood before proceeding with the tests described in thisStandard.