ASME B89.1.2M pdf download

ASME B89.1.2M pdf download Calibration of Gage Blocks by Contact Comparison Methods (Through 20 in. and 500 mm)

3.4 Micrometer Unit

The metric unit representing one millionth (1/1.000.000) of a meter was formerly expressed as onemicron,*and identified symbolically by the Greek let-ter u (mu). It has been replaced by the name “microm-eter’and identified by the symbol um, For reasons ofclarity the word “micrometer’ is always spelled out inthis Standard.One microinch equals 0.0254 micrometer.

4 ENVIRONMENT

4.1 Cleanliness

Clcanlincss must be maintained in the immediate vi-cinity of thc measurement being performed.The criticalsurfaces of the master gage block, the gage block beingcalibrated, and the measuring equipment must be cleanand free of foreign matter and dust particles.

4.2 Temperature

The international standard temperature, at which theactual length of a gage equals its nominal length, is 68“F(20°C). The actual temperature of test gage block, reference gage block, and instrument, must be known ifaccurate and reliable calibrations are to be achieved.The calibration accuracy may suffer when the ambienttemperature departs from standard,by an amount de-pending on the temperature difference and its rate ofchange, the length of the gage blocks, the materials ofwhich they are made,and the accuracy of the coefficients of thermal expansion used in making correctionsConditions will be improved by theral shielding ofthc measuring station, the use of a soaking plate, andthe knowledge of the exact temperature of the test blockand reference block as determined by temperature measuring devices.

It follows that, in order to achieve the level of accuracy required for the calibration of gage blocks. the deyiation of the environmental ambient temperature fromthe standard must be held to a minimum.A suggestedmaximum is + 0.5°F(0.25°C) or less.For a completcanalysis of the subject,refer to ANSI B8962-1973Temperature and Humidity Environment for Dimensional Measurement.

4.3Humidity

It is recommended that the relative humidity in themeasuring environment shall not exceed 45%.Humidity significantly beyond that value may cause problemswith rusting of iron and steel surfaces, and cause personnel discomnfort.

4.4 Vibration

Excessive mechanical vibration in the measurementlaboratory may seriously affect the accuracy required forgage block mcasurement by causing instability at thepoint of measurcment and at the readout Vibratiorshould be minimized by locating the laboratory awayfrom vibration sources and by using insulating mountings for measuring equipment,An ideal solution, usecby some laboratorics, is to support all measuring equipment on a massive floating subfloor isolated from thesurrounding structure, the building foundation and thework floor.

5 GAGE BLOCK GEOMETRY

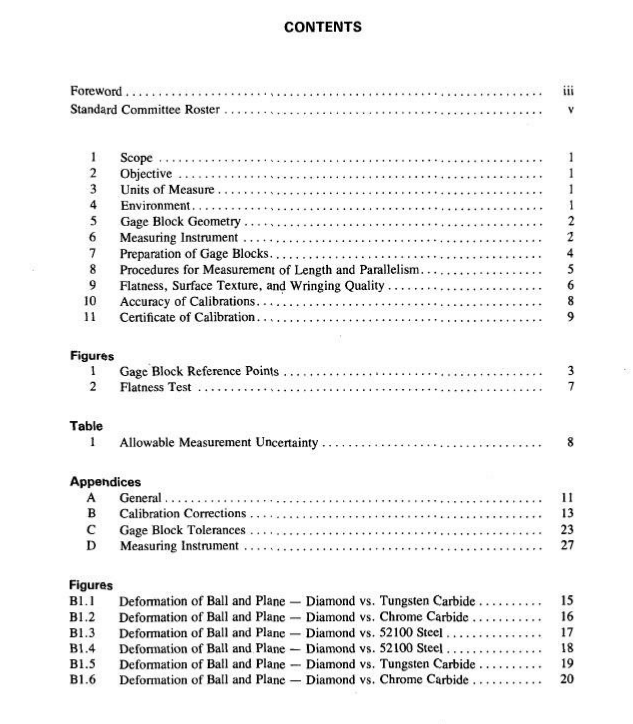

5.1 Shape

Gage blocks arc made in three cross sectional shapes:rectangular,square and round, with and without holes(see Fig.1).

5.2 Reference Points

The reference point is a point located in the plane ofeach gaging surface.The top reference point is locatedfor each shape in relation to the size marking as shownin Fig.1. The bottom reference point is the mirror image of’ the top reference point.