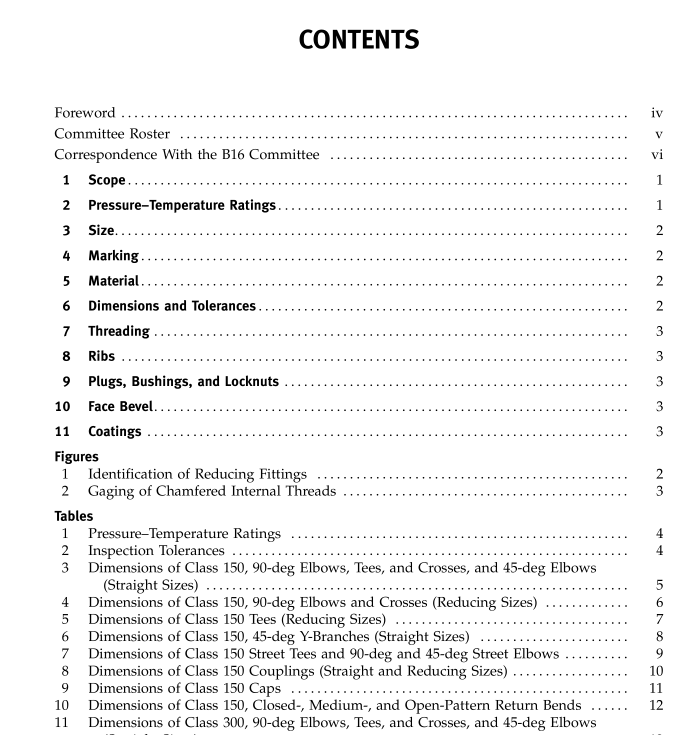

ASME B16 pdf download

ASME B16 pdf download Gray Iron Pipe Flanges and Flanged Fittings Classes 25, 125, and 250

3 PRESSURE–TEMPERATURE RATINGS

3.1 General Pressure–temperature ratings are maximum allowable workingpressures in bar (psi) units atthe temperature in degrees Celsius (Fahrenheit) shown in Tabl 3.1-1 for the applicable material and class designation. For inter- mediate temperatures, linear interpolation is permitted. Interpolationbetweenclass designations isnotpermitted.

3.2 Flanged Joints Aflanged jointis composed ofindependentinterrelated components: the flanges, gasket, and bolting, which are assembled manually. Proper controls must be exercised in the selection and application for these elements to attain a joint that has acceptable leak tightness. Special techniques, such as controlled bolt tightening described in ASME PCC-1, may be used to achieve a tight joint in service.

3.3 Rating Temperature Temperatures shown for the corresponding pressure rating shall be the material temperature of the pres- sure-retainingstructure. Itmaybeassumedthatthemate- rial temperature is the same as the fluid temperature. Use ofa pressure rating at a material temperature other than that ofthe contained fluid is the responsibility ofthe user and subjectto the requirements ofany applicable code or regulation.

3.4 Low-Temperature Ratings Pressure ratings fortemperatures below−29°C (−20°F) should be determined in accordance with low-tempera- ture properties ofgray iron (ASTM A126) as governed by applicable code or regulation.

3.5 Ductility Grayiron has little ductility; therefore, the resistance of these flanges and flanged fittings to excessive forces and suddenly applied loads is significantly less than for more ductile materials, such as steel. The following precautions are recommended:

(a) These flanges and flanged fittings should not be usedwhere suddenlyappliedloads such as rapid pressure fluctuation may occur.

(b) Alignment of flange faces is essential along with control of assembly bolt torque so as not to overstress the gray iron flanges. Care should also be exercised toensurethatpipingloadstransmittedtograyironflanges are controlled.

4 SIZE

4.1 Nominal Pipe Size As applied in this Standard, the use of the phrase “nominal pipe size” or the designation NPS followed by a dimensionless number is for the purpose ofidentifying the end connection of piping, flanges, or flanged fittings. The number is not necessarily the same as the flange or flanged fitting inside diameter.

4.2 Reducing Fittings Reducing fittings shall be designated by NPS for the openings in the sequence as indicated in the illustrations of Figure 4.2-1.

5 MARKING

5.1 Fittings The manufacturer’s name or trademark and numerals as shown belowforeach pressure ratingclass designation shall be cast on the exterior surface of all fittings.