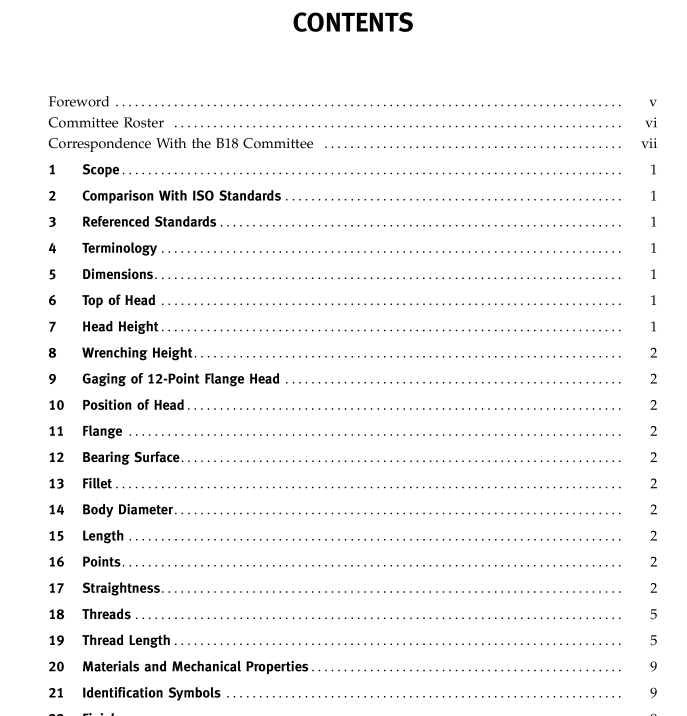

ASME B18.2.5M pdf download

ASME B18.2.5M pdf download Metric 12-Point Flange Screws

8 WRENCHING HEIGHT Corners of the 12 points shall be fully formed and reasonably uniform over the wrenching height, K w . Head drive root radius, R 4 , applies to the entire length of the wrenching height, K w (see Table 1).

9 GAGING OF 12-POINT FLANGE HEAD The head shall be gaged using two ring gages, A and B, to demonstrate the coincidental acceptability of wrenching height, corner fill, and width across corners. Gage A shall be placed over the head and shall seat on the flange. Gage B shall be placed on the top of the head normal to the screw axis. The two gages shall not be in contact (see Table 2).

10 POSITION OF HEAD At maximum material condition, the axis of the 12 points of the head shall be within a positional tolerance zone of the diameter specified in Table 3 with respect to the axis of the shank over a distance under the head equal to the nominal screw diameter, D. The datum shall be as close to the head as practicable, but within 0.5D from the head, and shall be either wholly plain body or wholly the thread major diameter, not including the thread runout or the underhead fillet.

11 FLANGE The top surface ofthe flange shallbe conical or slightly rounded (convex). Radius, R 2 , applies bothatthe corners and at the flats of the 12 points. The contour of edge at flange periphery, between the maximum flange diame- ter, D c maximum, and the minimum bearing circle diameter, D w minimum, shall be optional provided that the minimum flange edge thickness, C minimum, is main- tained at the minimum bearing circle diameter, D w minimum.

12 BEARING SURFACE The plane formed by the bearing circle shall be per- pendicular to the axis of the shank, over a length under the head equal to the nominal screw diameter, D, within the circular runout as specified in Table 3. The measurement of bearing face runout shall be made at the actual bearing circle (i.e., at the line of highest points on any radial line, e.g., by use ofstraight edge anvil).

The datum shall be as close to the head as practical, but within 0.5D from the head, and shall be either wholly plain body or wholly thread major diameter, not including the thread runout or the underhead fillet.

13 FILLET The fillet configuration at the junction of the head and shankshall conformto either Type F, as shownin Table 4,