ASME B107-60 pdf download

ASME B107-60 pdf download Pry Bars

1SCOPE

This Standard provides performance and safetyrequircments for pry bars that are intended for separat-ing prying.ripping, lifting scrapingand aligning applications. Therc are numerous varieties of pry bar designsand intended uses. Pry bars are not designed to bestruck. This Slandard covers specific types of pry barsand their intended safe uses.

This Standard is intended to serve as a guide in select-ing, testing, and using the hand tools covered herein. Itis not the purpose of this Standard to specify the detailsof manufacturing.

This Standard is also meant to serve as a guide indeveloping manuals and posters and for training personnel to work safely.

This Standard may be used as a guide by state authorities or other regulatory bodies in the formulation of lawsor regulations It is also intended far yoluntary use byestablishments that use or manufacture the toolscovered.

The methods employed to ensure compliance withthis Standard shall be determined by the proper regulatory or administrative authority.

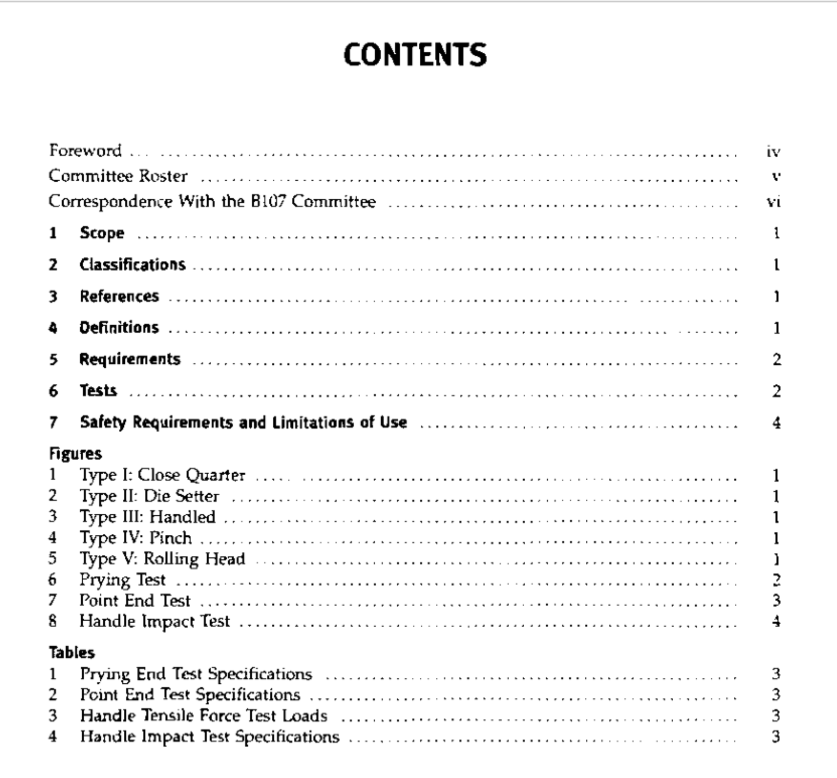

2 CLASSIFICATONSType I: Close Quarter (Fig.1)Type Il: Die Setter (Fig. 2)Type !II: Handled (Fig. 3)Type IV: Pinch (Fig. 4)Type V: Rolling Head (Fig.5)

REFERENCES

The fol!owing publications are referenced in thisStandard.

ANSI Z87.1, Practice for Occupational and EducaticnalEye and Face [rotectionANS] Z535.4, Producf Safety Signs and Labels

Publisher: American National Standards Institute(ANSI), 25 West 43rd Street, New York, NY 10036

ASTM E18, Standard Test Methods for Rockwell Hard-pess and Rockwell Superficia] Hardncss of Metallicaterials

Publisher: American Society for Testing and Materials(ASTM)100 Barr Harbor Drive. West Conshohocken.PA 19428

Guide to Hand Tools – Selection, Safety Tips, ProperUse and CarePublisher: Hand Tools Institute (HTI), 25 North Broad-way, Tarrytown,NY 10591-3201

4 DEFINITIONS

body: straight portion of bar (excluding the handle gripwhen provided) used for gripping during prying operation5.

chise! end: portion of bar having a tapered shape gradu-ally reducing to and including the prying edge.equitalenf: the word “equivalent” in this Standard shallbe interpreted to mean alternative designs or featuresthat will provide an equal degree of safety and per-formance.

handle: additional material that is securely attached tothe body and is to be gripped during use.point end: portion of bar having a tapered, round, crosssectional area that is intended for aligring applicatians.prying edge: edge formed by the tapering of the chiselend or claw end.

prying end: portion of bar having a chisel end or aclaw end.

safety message: informnation imprinted on or affixed tothe bar that is intended to promote safety.shal! and should: mandafory requirements of this Stan-dard are characterized by the word “shall.” [f a provisionis of an advisory nature, it is indicated by the word”should” or is stated as a recommendation.

5 REQUIREMENTS

Pry bars shall pass the tests specified in para. 6 asapplicable.

5.1 Design

5.1.1 Type l: Close Quarter, Pry bars shall have asharply bent chisel end providing leverage in limitedspace applications and a poinfed end for alignmentapplications.