ASME B107-56 pdf download

ASME B107-56 pdf download BOOY REPAIR HAMMERS AND DOl l ‘ BLOCKS: SAFETY REQUIREMENTS

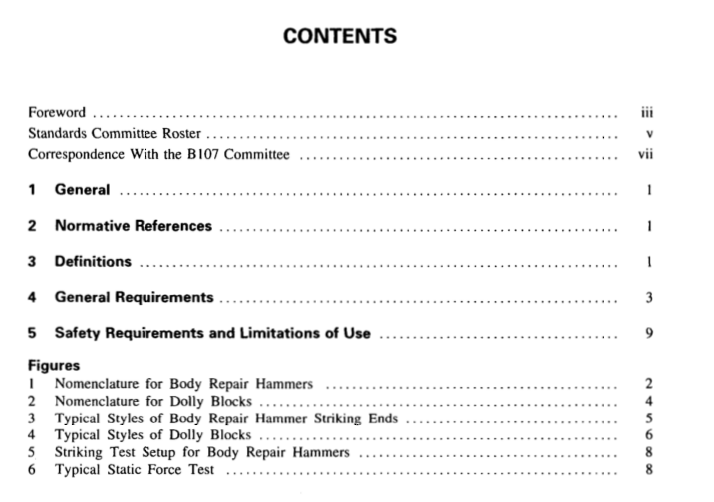

、4.1.2 The fender bumper has a striking surface anda struck face. See Fig. 3(e).

4.1.3 The chamfer on the bumping dinging, finishing.and other striking faces shall be a minimum of 0.010in.(0.25 mm).

4.1.4 Handles shall be of any design includingergonomic, that will withstand the appropriate testsspecified in paras.4.5.3 and 4.5.4.

4.1.5 The head and handle shall be free of nonfunctional sharp edges, points, and surface roughness thatcan inflict personal injury when handling the hammer.

4.2 Design of Dolly Blocks

Dolly blocks are designed for straightening, bumping.shrinking, and finishing sheet metal panels. They areintended for use with or without body repair hammers,but shall not be struck directly with a hammer.

4.2.1 Various typical styles of dolly blocks and theirfunctions are listed here (see Fig. 4). The namesgiven are those generally recognized in the body repairindustry. The styles covered by the Standard are notlimited to those named or illustrated.

(a) General Purpose, Crowned. For use on crownedpanels and filat portions of body panels.

(b) General Purpose, Anvil. For various curves andcontours of body, door panels, and deep skirted fenders.

(c) General Purpose, Rail. For bumping. dinging.straightening, and finishing various portions of bodydoor panels and fenders. A general purpose rail dollyblock has two beading and flanging edges.

(d) Bead. The working surfaces are suitable for useon long curved fenders, beads and flanges.

(e) Heel. The working surfaces are suitable for uscon sharp corners and large radius portions of panels.(f) Toe. Has a fat face and flat edge for use indinging flat surfaces. The crowned and curved contoursare suitable for use on odd crowns and contours.

(g) Wedge. The shape is suitable for use behindbrackets braces and reipforcements..

(h) Shrinking. Has a low crown suitable for shrinkingmetal, raising beads, and molding.

(i) Angle. For use on various angles, crosses andcurves.

(j) Spoon. Has an integral handle to allow formingin deep pockets of doors and panels.

4.2.2 All dolly block surfaces shall be free of non-functional sharp edges, points, and surface roughncssthat could inflict personal injury when handling thedolly block.

4.3 Materials

4.3.1 Body Repair Hammers

4.3.1.1 Body repair hammerheads shall be madefrom special-quality, fine-grain, hot-rolled steel barsconforming to the chemical requirements specified inASTM A 576.Equivalent material, such as alloy steelin conformance with ASTM A322 or ASTM A681,may also be used.

4.3.1.2 Body repair hammerheads shall be freeof manufacturing and material defects such as seams.laps, pipes, and cold shuts that would jeopardize soundconstruction.They shall conform to the requirementsfor mechanical properties specified in para. 4.4.1 andshall withstand the striking test specified in para. 4.5.3.4.3.1.3 Handles shall be made of any suitablematerial that will withstand the test requirements inparas.4.5.3 and 4.5.4.

4.3.2 Dolly Blocks

4.3.2.1 Dolly blocks shall be made from special-quality, fine-grained, hot-rolled carbon steel or alloysteel having good wear-resisting and shock-resistingqualities. Equivalent materials conforming to eitherASTM A29/A29M,ASTM A322,O ASTM A576 mayalso be used.