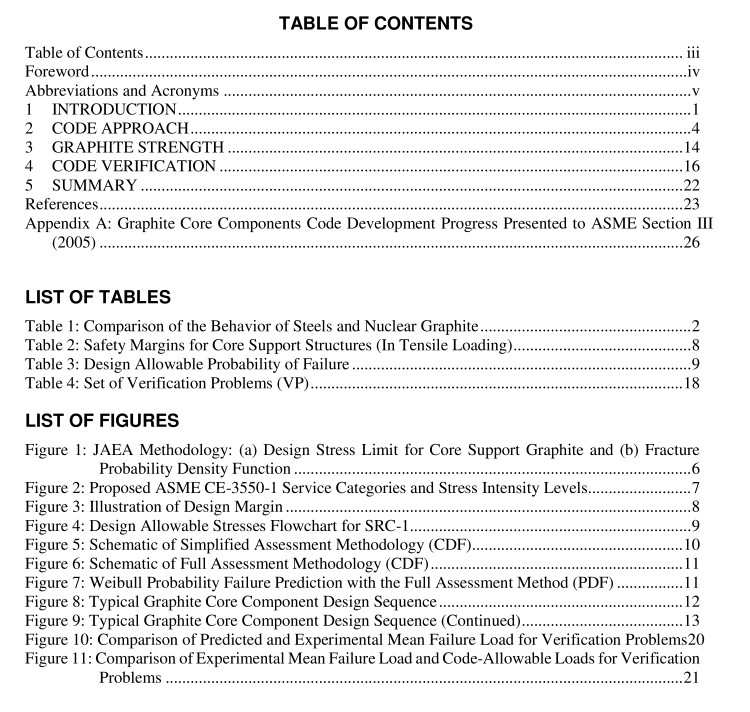

ASME NTB-4 pdf download

ASME NTB-4 pdf download Background Information for Addressing Adequacy or Optimization of ASME BPVC Section III, Division 5 Rules for Nonmetallic Core Components

INTRODUCTION

Before its appearance in the 201l edition of ASME BPVC, there was no internationally recognized graphitecore design code. Although the need for such a code was recognized by stakeholders such as the US NuclearRegulatory Commission (NRC) and several reactor designer/constructers, it was not until 2002 that ASMEformed a project team to initiate a graphite design code. Graphite is used extensively for reactor internalcomponents in high-temperature gas reactor concepts, as it is needed to establish core geometries allowingcoolant flow. reactivity control, and shutdown element insertion; serve as a moderator while supporting thenuclear heat generation process: and provide a passive heat removal flow path in certain licensing basisevents[1]

Those functions are key to the operation and safety of the reactor svstem. One critical difference betweengraphite core components and the pressure vessel is that the graphite core assembly is a structure comprisingmany hundreds of components, The designers take measures to ensure that the failure of a single componentdoes not compromise the function of the assembly

The prior approach to graphite design was deterministic, similar to the approach applied for metalliccomponents today. Graphite, with no strength in the plastic regime, was treated as a linear Hookeanmaterial. Any component that suffered cracking was considered a “failed component” and was removed.Additionally, only nonirradiated graphite use was addressed.This approach has been found to beinadequate for design and regulatory licensing. Graphite, because of its nature, is inherently cracked; andthe absence of cracking cannot be ensured nor used as an indicator of absolute reliability, as it can be formetals.

After assessment, a new probabilistic approach was adopted. It concluded that the designer can allow forcracks in the component but must demonstrate through analysis and testing that the component can maintainthe assigned safety function. Moreover, the design should account for the effects of irradiation on thethermal and mechanical properties of the graphite in the design of the graphite core and consider statisticalstrength variations within a billet, as well as variation from billet to billet due to different production runs.The new approach also does not follow the standard ASME practice of defining primary and secondarystresses but instead uses a combined stress approach that incorporates the largest stress contributors -irradiation-induced stresses and mechanical stress concentrations- as well as lesser stress contributorslike combined membrane, bending,and peak stresses.

It was initially envisioned that the design code would be applied for helium-cooled high-temperaturereactors, as that was the leading technology at the time.

The purpose of this document is to provide background information on the scope, development,andverification of elevated-temperature design and construction rules as defined in ASME BPVC Section IllDivision 5 Subsection HH, Class A Nonmetallic Core Support Structures, Subpart A Graphite Materials2017 edition. The general requirements applicable to nonmetallic core components are discussed in BPV(Subsection HA General Requirements, Subpart B, Graphite Materials.

Similar to the rules for metallic components, BPVC Section Ill, Division 5, High Temperature Reactors isstructured to provide a central location for all aspects of construction for high-temperature reactors.including nonmetallic components or, more specifically, graphite components, in the 2017 edition. Fornonmetallic components, according to ASME code terminology,“construction” includes all aspects ofMaterials (HHA-2000),Design (HHA-3000), Machining,Examination and Testing (HHA-4000).Installation and Examination (HHA-5000), and Nameplates (HHA-8000). The rules stipulate details formaterial specifications (HHA-I), the requirements for preparing a material data sheet (HHA-Il), and therequirements for generating design data for different graphite grades (HHA-Ill). It also gives referenceguidance for consideration of factors such as graphite as a structural material (HHA-A) and theenvironmental and oxidation effects in graphite (HHA-B).