ASME B89.7.3.1 pdf download

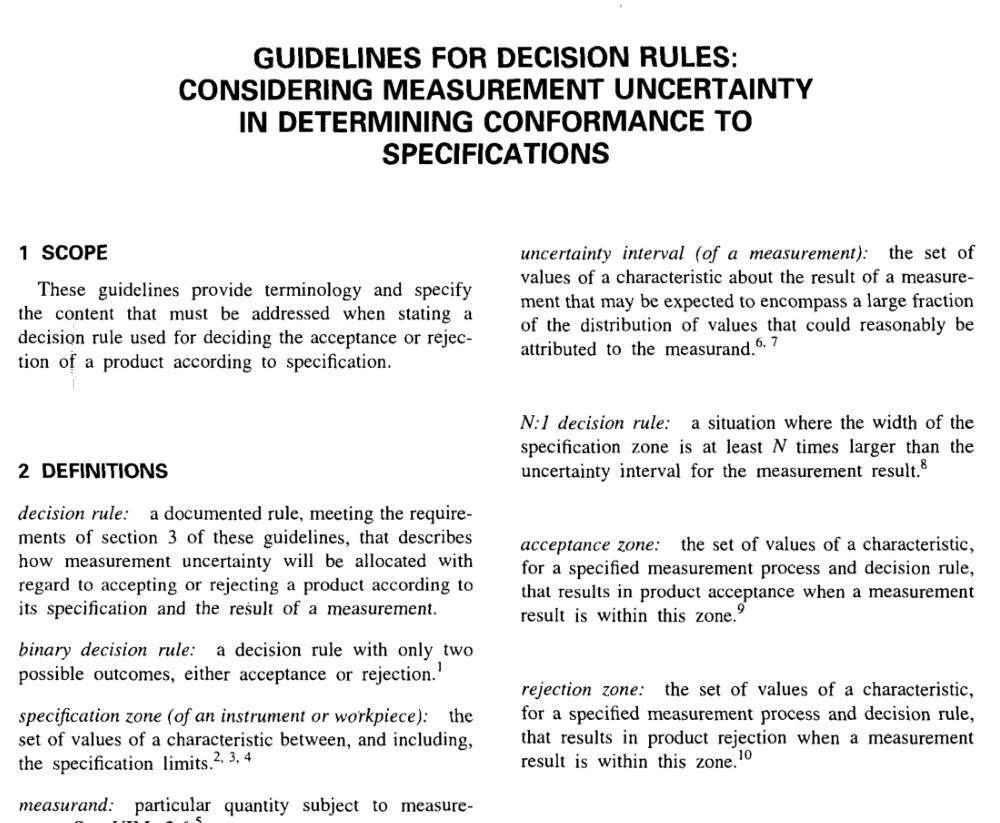

ASME B89.7.3.1 pdf download CUIDELINES FOR DECISION RULES: CONSIDERING MEASUREMENT UNCERTAINTY IN DETERMINING CONFORRIIANtE TO SPECIFICATIONS

3 REQUIREMENTS FOR DECISION RULES

3.1 Zone Identification A decision rule must have a well-documented method of determining the location of the acceptance, rejection, and any transition zones.

3.2 Decision Outcome Each zone of a decision rule must correspond to a documented decision that will be implemented should the result of measurement lie in that zone. While this is automatic for the acceptance and rejection zones by definition, any transition zones must have their corresponding decision outcome documented.

3.3 Repeated Measurements A decision rule must state the procedure for ad- dressing repeated measurements of the same characteris- tic on the same workpiece or instrument. See Appendix B for further discussion of this issue.

3.4 Data Rejection A decision rule must state the procedure for allowing data rejection with cause, that is, rejection of “outliers.” See Appendix C for further discussion of outliers.

4 ACCEPTANCE AND REJECTION ZONES IN DECISION RULES

4.1 Simple Acceptance and Rejection Using an N: Decision Rule This is the most common form of acceptance and rejection used in industry and is the descendant of MIL- STD 45662A. Simple acceptance means that product conformance is verified2’ if the measurement result lies in the specification zone and rejection is verified otherwise (see Fig. 2), provided that the magnitude of the measurement uncertainty interval is no larger than the fraction 1/N of the specification zone. In recent years, as tolerances have become increasingly tighter, the well-known ten-to-one ratio has transitioned to a more commonly used ratio of four-to-one (see MIL- STD 45662A) or even three-to-one (see International Standard 10012-1). A 4:l decision rule means the uncertainty interval associated with the measurement result should be no larger than one-fourth of the allow- able product variation, which requires the expanded uncertainty, U, to be no larger than one-eighth of the specification zone. Once the uncertainty requirement is satisfied, then the product is accepted if the measurement result lies within the specification zone and rejected otherwise. Note that instrumentation is sometimes speci- fied by a maximum permissible error (MPE), which places a limit on the magnitude of the error regardless of sign. Hence the specification zone has a width of twice the MPE, i.e., -tMPE, and a four-to-one ratio requires the expanded uncertainty to be one-fourth the MPE value; see Appendix D for further details. While the simple acceptance and rejection approach is straight- forward, difficulties develop for measurement results close to the specification limits. Even using the mean of repeated measurements, if the mean result is near the specification limit there may be a significant chance that a product characteristic with simple acceptance verified is actually out-of-specification and vice versa. To address this issue, an alternative decision rule based on “guard banding” can increase confidence in accept- ance decisions.