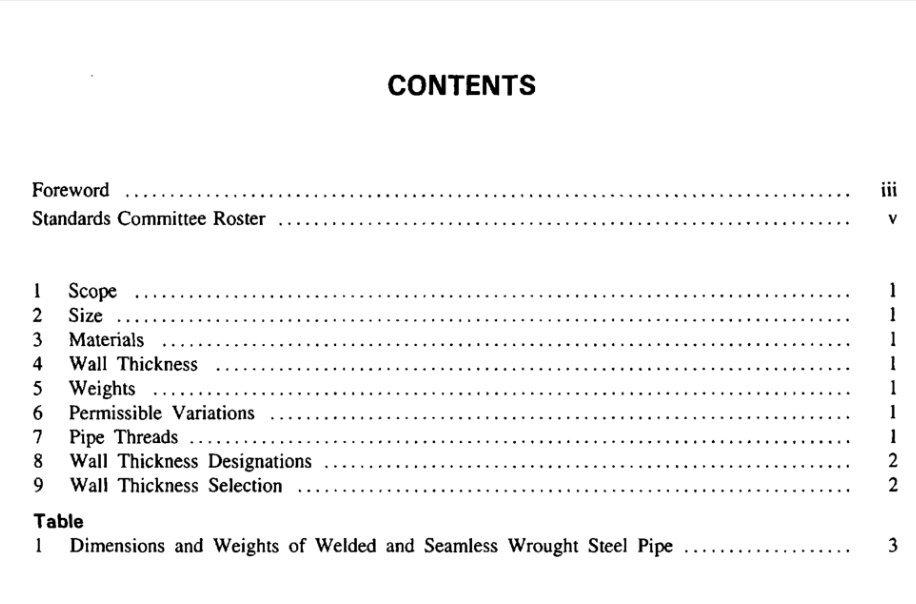

ASME B36.10M pdf download

ASME B36.10M pdf download WELDED AND SEAMLESS WROUGHT STEEL PIPE

1 SCOPE

This Standard covers the standardization of dimen-sions of welded and seamless wrought steel pipe forhigh or low temperatures and pressures.The word pipe is used as distinguished from tubeto apply to tubular products of dimensions commonlyused for pipeline and piping systems. Pipe NPS 12(DN 300) and smaller have outside diameters numerically larger than their corresponding sizes. In contrast.the outside diameters of tubes are numerically identicalto the size number for all sizes.

2 SIZE

The size of all pipe is identified by the nominalpipe size.The manufacture of pipe NPS (DN 6) to NPS12 (DN 300) inclusive is based on a standardizedoutside diameter (OD). This OD was originally selectedso that pipe with a standard OD and having a wallthickness that was typical of the period would havean inside diameter (ID) approximately equal to thenominal size. Although there is no such relation betweenthe existing standard thickness – OD and nominalsize – these nominal sizes and standard ODs continuein use as **standard.

The manufacture of pipe NPS 14 (DN 350) andlarger proceeds on the basis of an OD correspondingto the nominal size.

3 MATERIALS

The dimensional standards for pipe described hereare for products covered in ASTM specifications.

4 WALL THICKNESSThe nominal wall thicknesses are given in Table 1.

5 WEIGHTSThe nominal weights of steel pipe are calculatedvalues and are tabulated in Table 1.

The nominal plain end weight, in pounds per foot,is calculated using the following formula:

w= 10.69(D – 1)

whereWenominal plain end weight rounded to the”nearest 0.01 lb/ftD=outside diameter to the nearest 0.001 in. (thesymbol D is to be used for OD only inmathematical equations or formulas)specified wall thickness rounded to the near-1=est 0.001 in.

The nominal plain end mass, in kilograms per meter,is calculated using the following formula:

w= 0.0246615(D – 1)t

whereWe=nominal plain end weight rounded to the

nearest 0.01 kg/m

D=outside diameter to the nearest 0.1 mm foroutside diameters that are 16 in. (406.4 mm)and smaller and to the nearest l.0 mm foroutside diameters larger than 16 in. (406.4mm) (the symbol D is to be used for ODonly in mathematical equations or formulas)! specified wall thickness rounded to the near

est 0.01 mm

6 PERMISSIBLE VARIATIONS

Variations in dimensions differ depending upon themethod of manufacture employed in making the pipeto the various specifications available. Permissible varia-tions for dimensions are indicated in each specification.

7 PIPE THREADS

Unless otherwise specified, the threads of threadedpipe shall conform to ANSI/ASME B1.20.1, PipeThreads,General Purpose (Inch).Schedules 5 and 10 wall thicknesses do not permitthreading in accordance with ANSVASME B1.20.1.