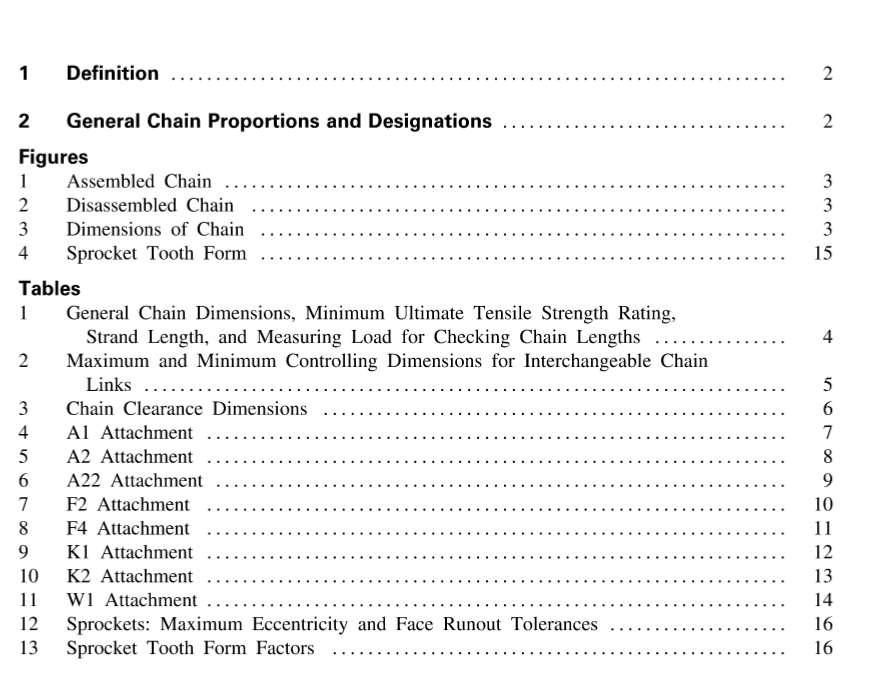

ASME B29.20 pdf download

ASME B29.20 pdf download WELDED-STEEL-TYPE MILLCHAINS,WELDED-STEEL-TYPEDRAG CHAINS, ATTACHMENTS, AND SPROCKET TEETH lImcorporating ASME B29.16M and A8ME B29.18M

1 DEFINITION

welded-steel-type mill chains: a series of identicalwelded offset links having barrels to contact the sprocketteeth,and pins which articulate in the barrels of thelinks.Pins are fixed in the sidebar pitch holes by eitherpress fits and/or mechanical locks,such as flats,toprevent rotation of the pins in the sidebar pitch holes.

2 GENERAL CHAIN PROPORTIONS AND DESIGNATIONS

2.1 Minimum Ultimate Tensile Strength

The minimum ultimate tensile strength (M.U.T.S.)for chain covered by this Standard, is the minimumforce at which an unused,undamaged,chain could failwhen subjected to a single tensile loading test.

(a) WARNING: The minimum ultimate tensilestrength is Nor a working load.” The M.U.T.S.

greatly exceeds the maximum force that may be appliedto the chain.

(b) Test procedure. A tensile force is slowly applied,in uniaxial direction,to the ends of the chain sample.(c) The tensile test is a destructive test.Even thoughthe chain may not visibly fail when subjected to theminimum ultimate tensile force,it will have been dam-aged and will be unfit for service.

2.2 Measuring Load

Measuring load should be 5 times the weight of 10ft of chain,rounded to the nearest 100 lbs.

2.3 Dimensions for Chain Links

To assure interchangeability of links as producedby different makers of chain,standard maximum andminimum dimensions are adopted. They are not actualdimensions used in manufacturing, but limiting dimen-sions,maximum or minimum,required to assure thedesired interchangeability. However, due to minor varia-tions in barrel configurations,coupling chains of differ-ent manufacture should be held to a minimum.