ASME B107.300 pdf download

ASME B107.300 pdf download Hand Torque Tools and Torque Testers

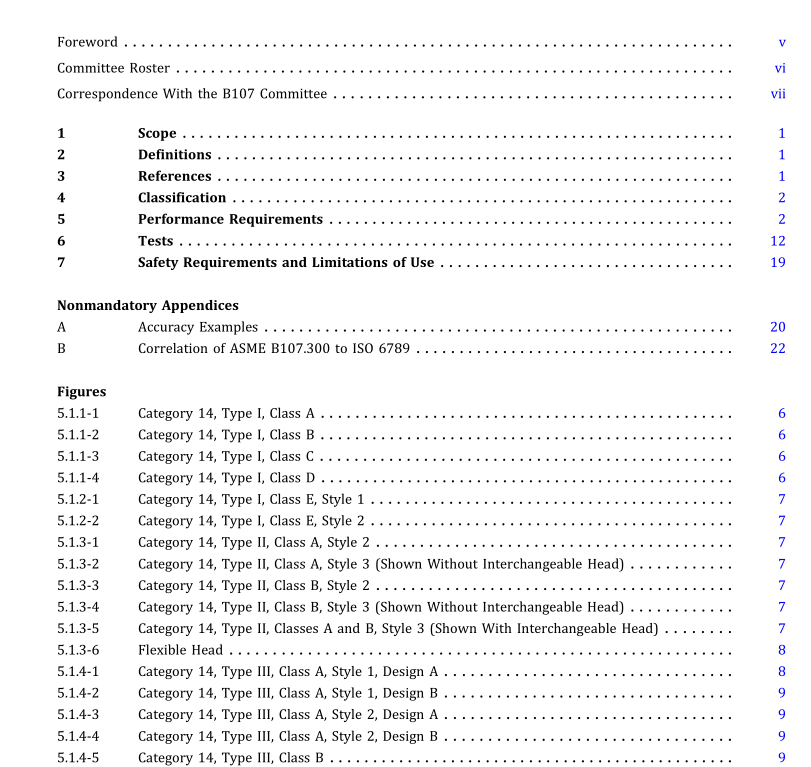

4 CLASSIFICATIONSee Tables 4-1, 4-2, and 4-3.

5 PERFORMANCE REQUIREMENTS

Figures are descriptive and not restrictive. They are notintended to preclude the manufacture or purchase ofotherforms of torque instruments conforming to this Standard.Torque instruments shall pass all applicable tests insection 6.

Unless otherwise specified,torque instruments shall becalibrated in the direction(s) of intended use.Torque instruments shall be capable ofbeing calibratedto the specified accuracy by a method traceable to theNational Institute of Standards and Technology (NIST].

5.1 Design – Category 14 Mechanical5.1.1 Type l, Classes A, B, C, and D – Indicating

(a) Operation.Instruments shall indicate torqueapplied through a deflecting member.They shalloperate in both clockwise and counterclockwise directions.

(1) Typel, ClassesAand B- Deflecting Beam. Flexingofa cantilever beam connectingthe square drive and handgrip shall provide the basis of operation. Type I, Class Adeflecting beam torque instruments may be similar to thatshown in Figure 5.1.1-1. Type l, Class B deflecting beamtorque instruments may be similar to that shown in Figure5.1.1-2.

(2) Type l, Classes C and D – Rigid Housing. Thedeflecting member and dial mechanism shall be enclosedwithin the rigid housing. The pointer and dial face shall beprotected by a transparent cover that shall be so locatedand constructed as to be reasonably free from accidentaldamage resulting from being struck or abraded. Type l,Class C rigid housing torque instruments may besimilar to that shown in Figure 5.1.1-3. Type l, Class Drigid housing torque instruments may be similar tothat shown in Figure 5.1.1-4.

(3) Type l Classes B and D – Interchangeable HeadConnection forAdapters and Extensions. The torque instru-ment shall be equipped with a connection, suitable foraccepting a variety of mating wrenching heads. Theconnection and standard wrenching heads shall be designed so that the requirements of para. 5.10 aremet throughout the specified accuracy range.Thewrenching heads shall comply with the requirementsof para. 5.7.Indicating torque instruments with an interchangeable head may be similar to Figure 5.1.1-2 (Class B)or Figure 5.1.1-4 (Class D).(b) Indicator A dial or scale shall be located to permitconvenient and accurate reading. The graduation marksshall be colored and shaped to be distinct and easily readThe width ofthe graduation mark shall not be greater thanone-halfthe adjacentspace width.Thewidth ofthe pointertip or indicator line shall not be greater than the widestgraduation mark, nor shall the pointer completely coverany graduation mark on the outer scale. The pointer shallbe located close to the scale face to meet the parallax errorrequirements of para 6.2.

(c) Hand Position. If, in order to achieve the requiredaccuracy,itis necessary to apply the load ataspecific pointon the hand grip, a pivot shall be located at that point.(d) Auxiliary Functions. Additional features may beincorporated on the torque instrument to improve accu-racy or usefulness. The inclusion ofsuch features shall notbe cause forrejection ofthe torque instrumentprovidingitconforms to the performance requirements of this Stan-dard.

(e) Type l, ClassesA, B, C, and D,Style 1- Plain Scale.Noauxiliary operational features are required.) Type l, Classes A, B, C and D, Style 2 – Scale WithSignal Mechanism. A signal mechanism capable of beingadjusted without the use of tools to any graduated value otthe instrument shall be provided. The signal shall operateautomatically within the accuracy requirements of thisStandard.

(g) Type l Classes A, B, C, and D, Style 3 – Scale WithMemory Indicator An auxiliary pointer or other devicecapable of retaining an indication of the maximumtorque transmitted through the instrument shall beprovided.The auxiliary pointer shall function at any graduatedtorque value within the accuracy requirements of thisStandard.Means shall be provided for resetting theauxiliary pointer.Normal handling of the instrumentshall not cause the auxiliary pointer to be displaced.