ASME A15.8 pdf download

ASME A15.8 pdf download CHUCKS AND CHUCK JAWS

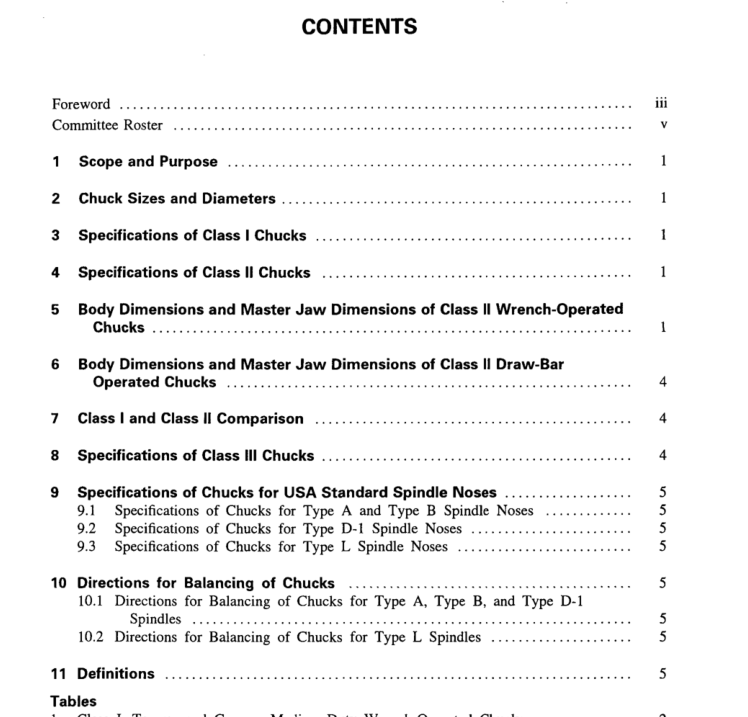

9 SPECIFICATIONS OF CHUCKS FOR USA STANDARD SPINDLE NOSES

9.1 Specifications of Chucks for Type A and Type B Spindle Noses Chucks for Type A and Type B spindle noses shall have the mounting made to the dimensions of Table 4 of ANSI B5.9-1967.

9.2 Specifications of Chucks for Type D-I Spindle Noses Chucks for Type D-1 spindle noses shall have the mounting made to the dimensions shown in Tables 7, 9, 11, or 13 of ANSI B5.9-1967.

9.3 Specifications of Chucks for Type L Spindle Noses Chucks for Type L spindle noses shall have the mounting made to the dimensions given in Table 29 of ANSI B5.9-1967.

10 DIRECTIONS FOR BALANCING OF CHUCKS

10.1 Directions for Balancing of Chucks for Type A, Type B, and Type D-I Spindles When chucks for Type A, Type B, or Type D-1 spindles are to be balanced, such chucks shall be balanced on an arbor that has itself previously been balanced without the chuck being mounted on it. The location of the cap screws, bolts, or studs for holding such chuck to the arbor must also be in balance. (See Table 5 of ANSI B5.9-1967.) 10.2 Directions for Balancing of Chucks for Type L Spindles When chucks for Type L spindles are to be balanced, the driving keyway shall have been previously finish machined in the taper. Such chucks shall then be balanced on a taper arbor provided with a full key and two screws holding the key in place, the taper, keyseat, key and two screws to be according to Table 28 of ANSI B5.9-1967. Such taper arbor shall have been previously balanced with a partial key that fills the keyseat and has an outside contour that coincides with the taper. To run in balance with such chucks, the Type L spindle should be balanced with a partiai key that fills the keyseat and has an outside contour that coincides with the taper.

11 DEFINITIONS chuck: as covered by this Standard, a workpiece holding device to be mounted on a machine spindle as further described in combination chuck, draw-bar oper- ated chuck, independent chuck, self-centering chuck, and wrench-operated chuck.

chuck body: that part of the chuck that encloses the operating mechanism for opening and closing the master jaws. It may be made of two pieces, if required, by the chuck design. combination chuck: a chuck in which are combined features of both the independent and self-centering chucks. The work holding jaws may collectively be moved as in self-centering chuck and/or individually adjusted as in an independent chuck.

This chuck may have either three or four jaws and is intended for use in holding work pieces of any form or outline, eccentrically or concentrically. draw-bar operated chuck: a chuck in which the jaws are opened or closed by means connected to an operating bar or tube located on the central axis of the chuck and extending through the spindle of the machine tool on which the chuck is mounted. The operating bar or tube is usually actuated by an air cylinder, a hydraulic cylinder, or other power means located at the rear end of the spindle.