IEC TR 61901 pdf download

IEC TR 61901 pdf download Development tests recommended on cables with a longitudinally applied metal foil for rated voltages above 30 kV (U m = 36 kV)

1 Scope

This technical report details the tests recommended for use when cables with a longitudinally applied metal foil are being developed.

The tests in this technical report are grouped as follows:

– tests on cable components (see Clause 2);

– first set of tests on completed cables (see Clause 3);

– second set of tests on completed cables (see Clause 4);

– third set of tests on completed cables (see Clause 5).

2 Tests on cable components

Specimens for control measurements should be removed from cable samples before any tests.

Specimens should also be removed from cable samples after the following tests:

– bending test (see 3.2);

– heating cycle test (see 3.3);

– water penetration test (see 3.4);

– corrosion test (see 3.6);

– short-circuit test (see Clause 4);

– sidewall pressure test (see 5.2).

The adhesion strength and the peel strength of the overlapped metal foil should be measured using the procedures of IEC 60840, G.2.1 and G.3.1 respectively.

3 First set of tests on completed cables

3.1 Test sequence

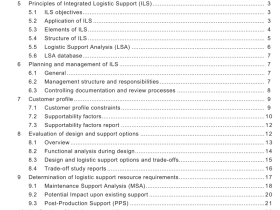

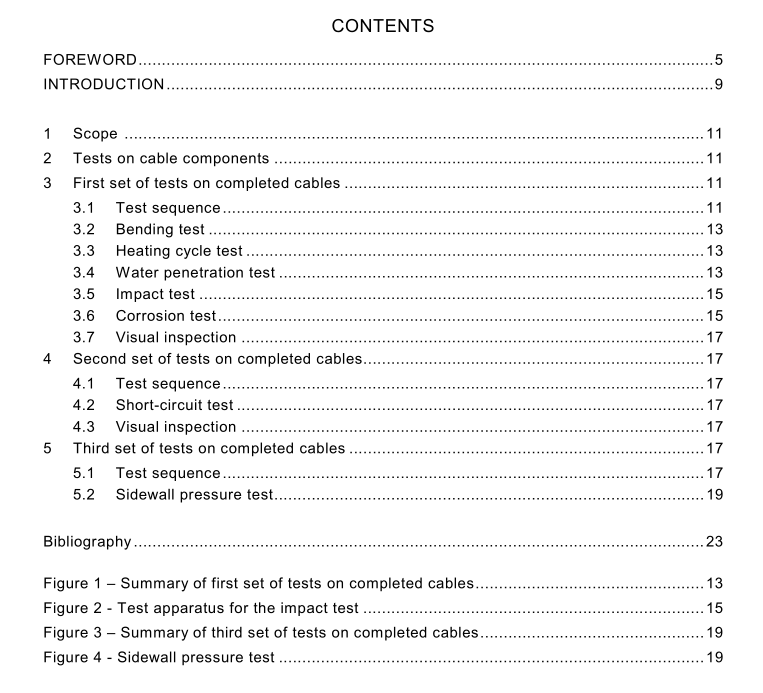

The sequence of tests is summarised in Figure 1 below.

3.2 Bending test

The bending test should be performed in accordance with IEC 60840, 1 2.3.3.

A 1 m sample should then be taken from the cable length and subjected to a visual inspection (see 3.7).

3.3 Heating cycle test

The test should be performed in accordance with IEC 60840, 1 2.3.6, except that no voltage is applied to the cable.

A 1 m sample should then be taken from the cable length and subjected to a visual inspection (see 3.7).

3.4 Water penetration test

This test should be performed in accordance with IEC 60840, 1 2.4.1 8, when applicable.

The sample should then be subjected to a visual inspection (see 3.7).

3.5 Impact test

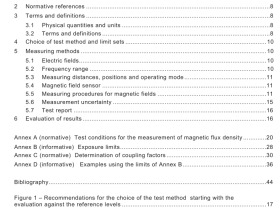

The cable, at least 1 m in length, should be installed on a rigid metallic base. The test should be undertaken at (20 ± 1 5) o C using a weighted metal wedge of 5 kg falling onto the cable from a height of 1 m. The 90° wedge should have a 2 mm radius of curvature at the point of impact and its axis should be perpendicular to that of the cable (see Figure 2).

One impact should successively be made at five different points along the cable, the distance between two impact points should be at least 1 00 mm.

Two samples should be subjected to the test:

− one for a corrosion test (see 3.6);

− one for visual inspection (see 3.7).

3.6 Corrosion test

A 1 m sample should be placed in a solution of 1 % NaCl, 1 % Na 2 SO 4 with NaOH added to adjust the pH of the solution to (8,5 ± 0,5).

The solution should be maintained at (70 ± 3) °C during the test. The cable with both ends sealed should be immersed at a depth of at least 0,5 m.

The cable sample should be removed from the solution after 3 000 h immersion and the metal foil inspected (see 3.7).