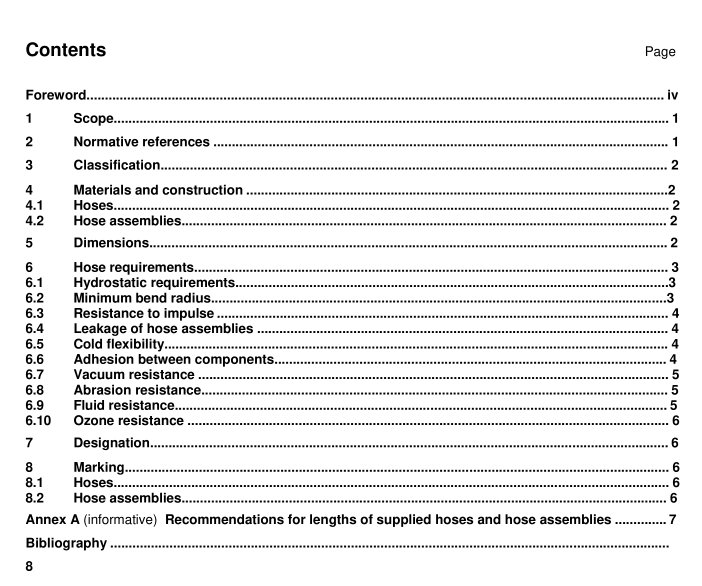

BS ISO 11237-1 pdf download

BS ISO 11237-1 pdf download Rubber hoses and hose assemblies — Wire-braid-reinforced compact types for hydraulic applications — Specification — Part

1: Oil-based fluid applications

1 Scope

This part of ISO 1 1 237 specifies requirements for three types of wire-braid-reinforced compact hose and hose assembly of nominal bore from 6,3 to 31 ,5. They are suitable for use with hydraulic fluids HH, HL, HM, HR and HV in accordance with ISO 6743-4 at temperatures ranging from −40 °C to +1 00 °C.

This part of ISO 1 1 237 does not include requirements for end fittings. It is limited to the performance of hoses and hose assemblies.

NOTE It is the responsibility of the user, in consultation with the hose manufacturer, to establish compatibility of the hose with the fluid to be used.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1 402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1 81 7, Rubber, vulcanized — Determination of the effect of liquids

ISO 4671 , Rubber and plastics hoses and hose assemblies — Methods of measurement of dimensions

ISO 4672:1 997, Rubber and plastics hoses — Sub-ambient temperature flexibility tests

ISO 6803, Rubber or plastics hoses and hose assemblies — Hydraulic pressure impulse test without flexing

ISO 6945, Rubber hoses — Determination of abrasion resistance of the outer cover

ISO 7233, Rubber and plastics hoses and hose assemblies — Determination of suction resistance

ISO 7326:1 991 , Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8033:1 991 , Rubber and plastics hose — Determination of adhesion between components

3 Classification

Three types of hose are specified, distinguished by their construction, working pressure, minimum bend radius

and oil resistance:

a) Type 1 SC, hoses with a single braid of wire reinforcement;

b) Type 2SC, hoses with two braids of wire reinforcement;

c) Type R16, hoses with one or two braids of wire reinforcement;

d) Type R17, 21 0 bar constant-pressure hoses with one or two braids of wire reinforcement.

NOTE Type R1 6 and R1 7 are not subjected to the vacuum resistance or abrasion resistance tests.

4 Materials and construction

4.1 Hoses

Hoses shall consist of a hydraulic fluid resistant rubber lining, one or two layers of high tensile steel wire and

an oil and weather resistant rubber cover.

4.2 Hose assemblies

Hose assemblies shall only be manufactured with those hose fittings whose functionality conforms to the requirements of 6.1 , 6.3 and 6.4 of this part of ISO 1 1 237.

The manufacturer’s instructions for proper preparation and fabrication of hose assemblies shall be followed.

5 Dimensions

When measured in accordance with ISO 4671 , the dimensions of the hoses shall conform to the values given in Table 1 .