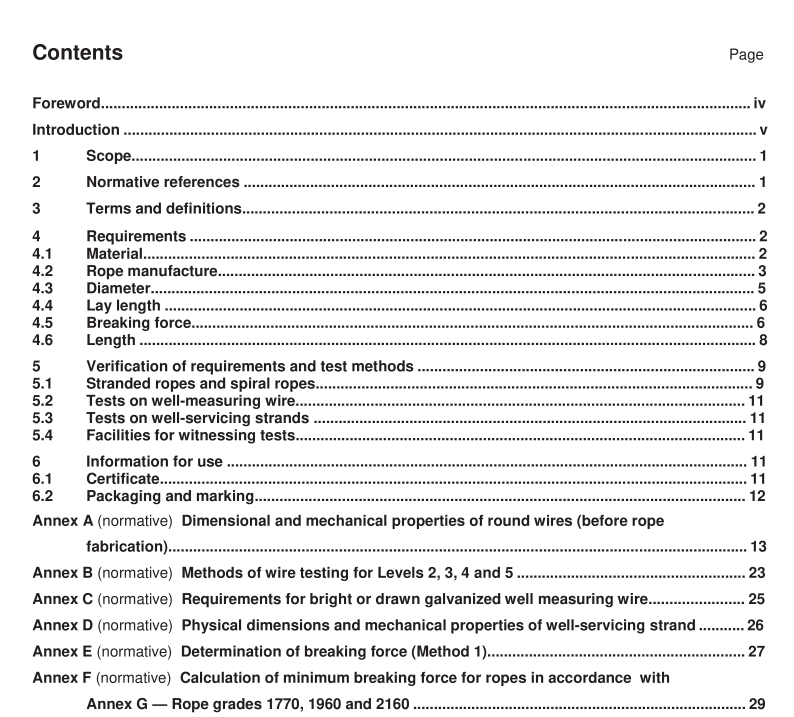

BS ISO 10425 pdf download

BS ISO 10425 pdf download Steel wire ropes for the petroleum and natural gas industries — Minimum requirements and terms of acceptance

Scope

This International Standard specifies the minimum requirements and terms of acceptance for the manufactureand testing of steel wire ropes not exceeding rope grade 2160 for the petroleum and natural gas industries.

Typical applications include tubing lines, rod hanger lines, sand lines, cable-tool driling and clean out linescable tool casing lines, rotary driling lines, winch lines, horse head pumping unit lines, torpedo lines.mast-raising lines, guideline tensioner lines, riser tensioner lines, mooring and anchor lines. Ropes for liftingslings and cranes, and wire for well-measuring and strand for well-servicing, are also included.

The minimum breaking forces for the more common sizes, grades and constructions of stranded rope aregiven in tables. However, this International Standard does not restrict itself to the classes covered by thosetables. Other types, such as ropes with compacted strands and compacted (swaged) ropes, may also conformwith its requirements. The minimum breaking force values for these ropes are provided by the manufacturer.

For information only, other tables present the minimum breaking forces for large diameter stranded and spiralropes (i.e. spiral strand and locked coi), while approximate nominal length masses for the more commonstranded rope constructions and large diameter stranded and spiral ropes are also given.

2 Normative references

The following referenced documents are indispensable for the application of this document. For datedreferences, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

SO 2232:1990, Round drawn wire for general purpose non-alloy steel wire ropes and for large diameter steelwire ropes – Specifications

ISO 4345,Steel wire ropes — Fibre main cores — Specification

SO 4346, Steel wire ropes for general purposes – Lubricants — Basic requirements

ISO 6892. Metallic materials — Tensile testing at ambient temperature

SO 7500-1, Metallic materials 一 Verification of static uniaxial testing machines -Part 1:Tension/compression testing machines — Verification and calibration of the force-measuring system

SO 7800, Metallic materials – Wire – Simple torsion test

SO 7801, Metallic materials – Wire – Reverse bend test

ISO 178932), Steel wire ropes 一 Definitions, designations and classifications

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 1 7893 apply.

4 Requirements

4.1 Material

4.1.1 Wire

The wires for stranded ropes and well-servicing strand of carbon steel shall, before rope fabrication, conform to the diameter, tensile, torsion and, when applicable, zinc-coating requirements specified in Annex A.

The methods of test for wires of tensile strength grades 1 370 N/mm 2 , 1 570 N/mm 2 , 1 770 N/mm 2 ,1 960 N/mm 2 and 2 1 60 N/mm 2 shall be in accordance with those given in ISO 2232.

The methods of test for wires of tensile strength grades Levels 2, 3, 4 and 5 shall be in accordance with Annex B.

For those ropes where a rope grade is applicable, the tensile strength grade of the wires shall be subject to the limits given in Table 1 .

NOTE The minimum breaking force values of those ropes of grades 1 770, 1 960 and 21 60 as covered by the tables are calculated on the basis of rope grade and not individual wire tensile strength grades or levels.