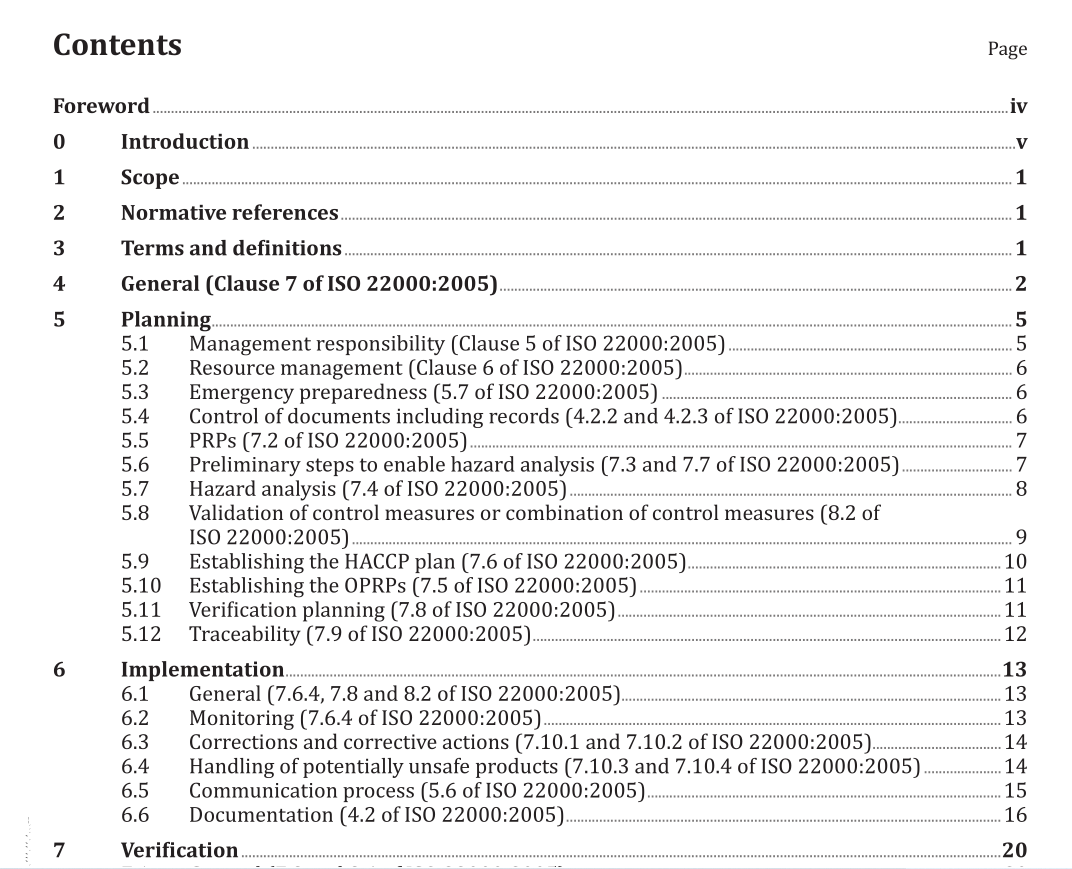

ISO 22004 pdf download

ISO 22004 pdf download Food safety management systems — Guidance on the application of ISO 22000

Scope

This International Standard provides generic advice on the application of ISO 22000

This International Standard does not create, alter or replace any of the requirements in ISO 22000.As individual organizations are free to choose the necessary methods and approaches to fulfil therequirements of ISO 22000, the guidance provided by this International Standard, are under nocircumstances, to be considered a requirement.

This International Standard has been drafted to enhance acceptance and use of ISO 22000-basedfood safety management systems (FSMS), as well as to improve understanding, communication andcoordination between organizations in the food chain.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and areindispensable to its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies.ISO 22000:2005, Food safety management systems – Requirements for any organization in the food chain

3 Terms and definitions

For the purposes ofthis document, the terms and definitions given in ISO 22000 and the following apply

NOTEIn the context of food safety, the terms “hazard” and “risk” are still translated into and/or used forthe single word: “risk” thus leading to the use of the incorrect expression “risk analysis” instead of the correctexpression“hazard analysis”(see 3.3 ofISO 22000:2005).

31significant hazardbiological, chemical or physical hazard, identified through the hazard analysis process, which needsto be controlled at critical control point(s) (CCP(s)l, or by operational PRP(S) and/or by combinationsthereof

Note 1 to entry: Lack of control will lead to a potentially unsafe product. Identified hazards, not assessed assignificant,need not be controlled at CCP(s) and/or by operational PRP(s).

Note 2 to entry: Operational prerequisite programme is abbreviated as OPRP

3.2

deviation

failure to meet an expected outcome

3.3

action limit

action criterionmeasurable or observable criterion established for the monitoring of a control measure applied as anOPRP

Note 1 to entry: An action limit or criterion expresses whether or not the control measure is under control, anddistinguishes between what is acceptable (limit met or achieved means the control measure is operating asintended) and unacceptable (limit not met nor achieved means the control measure is not operating as intended)

General(Clause 7 ofISO 22000:2005)

ISO 22000 requires the application of a dynamic and systematic process approach to the developmentdocumentation,implementation and maintenance of an FSMS This is achieved through effectiveplanning, coordination,implementation, verification and updating ofactivities, and through appropriateactions in the event of nonconformity.

The FSMS is developed and implemented through a Plan-Do-Check-Act (PDCA) approach as follows:

planning (Plan)ofthe steps; from the establishment ofthe PRPs, hazard analysis and critical controlapoint (HACCP) plan and/or by similar means for OPRP such as an OPRP plan (see Note below)through conducting hazard analysis and validating the selected control measures, to establishingverification procedures and developing a system for traceability;

NOTEAn OPRP plan is a controlled document that describes how the food safety hazards are managedand controlled by OPRPs.

6implementation (Do) of monitoring, corrections, corrective actions and handling of unsafe products(day-to-day operations);

verification (Check) of PRPs, control measures and system performance;

improvement(Act) by reviewing the overall system performance (management review), updating ofthe system and/or enhancing its effectiveness.