IEC 60749-15 pdf download

IEC 60749-15 pdf download Semiconductor devices – Mechanical and climatic test methods – Part 15: Resistance to soldering temperature for through-hole mounted devices

5 Procedure

5.1Pre-conditioning of specimens Any special pre-conditioning of the specimens prior to testing shall be as specified in the relevant specification. This preparation may include operations such as bending or other relocation of leads, and the attachment of heat sinks or protective shielding prior to solder dipping.

5.2Preparation of the solder bath The molten solder shall be stirred to assure that the temperature is uniform. The dross shall be skimmed from the surface of the molten solder just prior to dipping the part.

5.3Use of flux

Where detailed in the relevant specification, all leads of the specimen shall be dipped in fluxprior to solder dip; excess flux shall be removed by draining for a suitable time.

5.4Solder dip

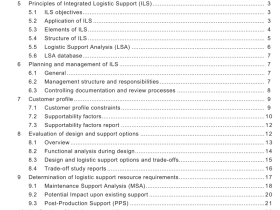

The part shall be attached to the dipping device (see 3.2) and the leads immersed in themolten solder until the body of the device under test reaches the dimensions specified inTable 1.The parameters for solder temperature, dwell time,number of immersions and ratesof immersion and emersion are defined in Table 1. Unless otherwise detailed in theprocurement specification, Condition A shall be used. After the dipping process, the part shallbe allowed to cool in air and,if flux has been used,residues shall be removed withisopropanol or ethanol.

5.5Precautions

Prior to and after the solder immersion,precautionary measures shall be taken to preventundue exposure of the part to the heat radiated by the solder bath.

5.6 Measurements

Hermeticity tests for hermetic devices,visual examination and electrical measurements thatconsist of parametric and functional tests,shall be made as specified in the relevantspecification.

5.7 Failure criteria

A device shall be defined as a failure if hermeticity for hermetic devices cannot bedemonstrated,if parametric limits are exceeded or if functionality cannot be demonstratedunder nominal and worst-case conditions specified in the relevant specification. Mechanicaldamage such as cracking, chipping or breaking of the package (10x -20x magnification) willalso be considered a failure, provided such damage was not induced by fixturing or handling.

6 Summary

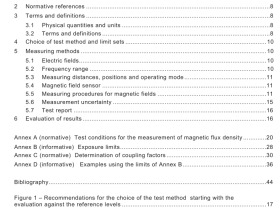

The following details shall be specified in the relevant specification:

a) use of heatsinks or shielding, if applicable (see 3.3);

b) flux composition if applicable (see 5.3);

c) older composition if other than detailed in this standard (see 4.1 );

d) pre-conditioning of specimens, if applicable (see 5.1 );

e) condition (A or B), time and depth of immersion, if other than as specified in Table 1 ;

f) method of hermeticity tests, visual examination and electrical measurements (see 5.6);

g) failure criteria of hermeticity tests, visual examination and electrical measurements (see 5.7);

h) sample size.