BS ISO 17907 pdf download

BS ISO 17907 pdf download Ships and marine technology — Single point mooring arrangements for conventional tankers

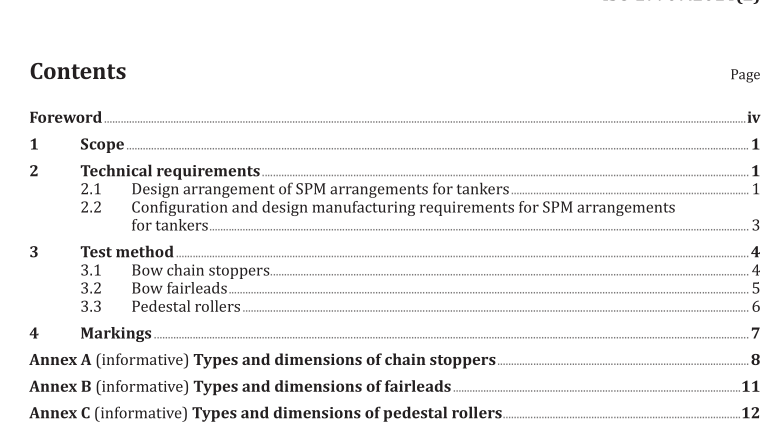

1 Scope

This International Standard specifies the technical requirements and test methods for the equipment necessary for the ships intended to use single point mooring (hereinafter referred to as “SPM”) arrangements, such as bow chain stoppers, bow fairleads, and pedestal rollers.

This International Standard is applicable to the SPM arrangements provided for tankers, gas carriers,and chemical vessels.

2 Technical requirements

2.1 Design arrangement of SPM arrangements for tankers

The general design arrangement is given in Figure 1 and Figure 2.

2.2

2.2.1 Bow chain stoppers

a) The configuration and load requirements are given in Table 1.

b) The general types of bow chain stoppers are given in Annex A

In the closed position, the design shall be such that it can prevent chafe chains from throw-out dueCto the sudden release.

d) The operating force of bow chain stoppers shall be not more than 245 N.

e)Materials can be weldable cast steel, forged steel, or rolled steel, which conform to the correspondingmanufacturing standard.

f)The product shall be free from defects that affect its use, such as cracks, sand holes, and pores

When the chain stopper is welded to the foundation, the weld strength shall be capable ofgwithstanding 2,0 times the SWL; when it is bolted to the foundation, effective thrust blocks shall beprovided to reduce shear.

When the ship is provided with the bow chain stopper of an emergency towing arrangemenththe SPM bow chain stopper may also be used as the bow chain stopper of the emergency towingarrangement.

2.2.2 Bow fairleads

The configuration and load requirements shall be consistent with those of the matching SPM bowalchain stoppers.

b) The general type of bow fairleads is given in Annex B

The bow fairlead shall be of closed type, with the opening dimensions of at least 600 mm in widthcand 450 mm in height.

dThe strength should be sufficient for all relevant angles of towline, i.e. up to 90° from the ship’scentreline to port and starboard and 30° vertical upwards and downwards.

Materials can be weldable cast steel,forged steel, or rolled steel, which conform to the correspondingmanufacturing standard.

The product shall be free from defects that affect its use, such as cracks, sand holes, and pores.