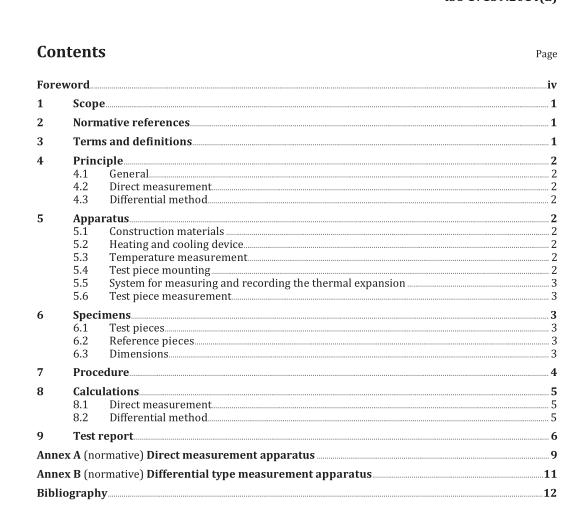

BS ISO 17139 pdf download

BS ISO 17139 pdf download Fine ceramics (advanced ceramics, advanced technical ceramics) — Thermophysical properties of ceramic composites — Determination of thermal expansion

4 Principle

4.1 General A test piece is heated and subsequently cooled, either at a specified uniform rate or using defined temperature increments. Its change of length and its temperature are measured continuously, or at regular frequent intervals during the imposed temperature cycle. One of two methods can be used to determine the linear thermal expansion coefficient, either by direct measurement or by a differential method.

4.2 Direct measurement In this method, the variation in length of the test piece is measured directly. It is necessary to know the change in dimensions of the test piece support system by previous calibration. The test piece is placed in a specimen holder and is made to contact a displacement transducer by using a push rod, made of the same material as the holder. This assembly is put in a furnace. The differential expansion between the test piece and the test piece holder is measured during the increase and the decrease in temperature. The apparatus is shown in Figure 1.

4.3 Differential method This method consists of measuring the changes in length between a reference piece (6.2) and the test piece. It is not therefore necessary to know the change in dimensions of the test piece support system. The apparatus is shown in Figure 2.

5 Apparatus

5.1 Construction materials The test piece holder and the push rod shall be made from thermomechanically stable materials of the same type, which shall be chemically inert and thermally compatible with the test piece material under the environmental conditions of the test. NOTE For temperatures above 1 400 °C, it is necessary to employ a vacuum or inert gas atmosphere, with a non-oxide material appropriate for the test environment, such as a grade of dense graphite.

5.2 Heating and cooling device Furnace, capable of working in a controlled atmosphere when required, and of controlling the temperature of the test piece to within 1 % of its mean temperature, expressed in K.

5.3 Temperature measurement Thermocouples, in accordance with IEC 60584-1, subject to the upper temperature requirements and environmental consideration, except for tungsten-rhenium couples which may be used at higher temperatures but are not covered by IEC 60584-1, should be individually calibrated. For temperature in excess of 2 000 K, infrared detectors or any suitable device may be used.

5.4 Test piece mounting The device used shall allow free axial movement of the test piece and of the reference piece in case of differential measurement. The mechanical environment shall minimize stresses. For vertical