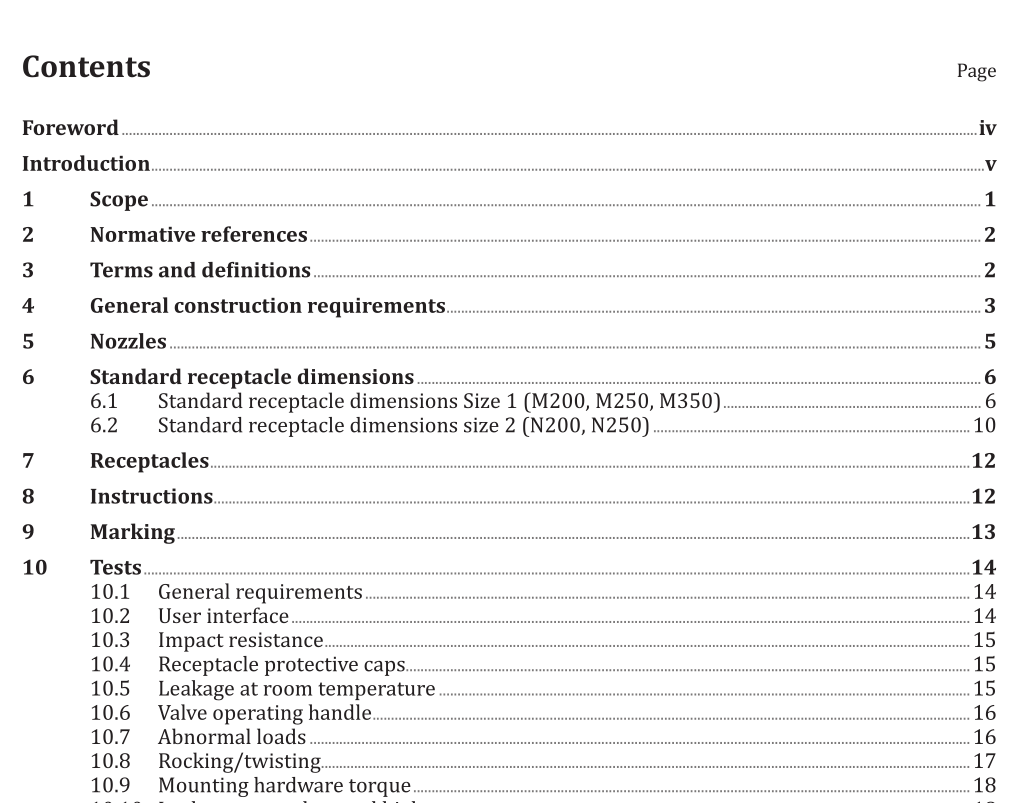

BS ISO 16380 pdf download

BS ISO 16380 pdf download Road vehicles — Blended fuels refuelling connector

4.4 Compressed blended fuels nozzles and receptacles shall be constructed out of materials which have to be proven for the intent of withstanding a blended fuels mixture at the given pressures, temperatures, and contents of the fuel that can be expected in this system.

4.5 Separate external three-way valves shall be constructed and marked so as to indicate clearly the open, shut, and vent positions.

4.6 Compressed blended fuels nozzles and receptacles shall be operated either to connect or disconnect without the use of tools.

4.7 Jointing components shall provide gas tight sealing performance. Unless otherwise specified, all tests shall be conducted using dry hydrogen, helium, or blends of nitrogen with a minimum 5 % of hydrogen. Test shall be performed by qualified personnel and appropriate safety measures shall be taken. The dew point of the test gas at the test pressure shall be at the temperature at which there is no icing, or hydrate or liquid formation. The dew point of the test gas at the test pressure shall be at the temperature at which there is no icing, or hydrate or liquid formation.

5 Nozzles

5.1 Nozzles shall be one of three types as described in a) to c). (See also Annex A)

a) Type 1, which is a nozzle for use with dispensing hoses that remain fully pressurized at dispenser shutdown. The nozzle shall not allow gas to flow until a positive connection has been achieved. The nozzle shall be equipped with an integral valve or valves, incorporating an operating mechanism which first stops the supply of gas and safely vents the trapped gas before allowing the disconnection of the nozzle from the receptacle. The operating mechanism shall ensure the vent valve is in the open position before the release mechanism can be operated and the gas located between the nozzle shut-off valve and the receptacle check valve is safely vented prior to nozzle disconnection (see 10.2).

b) Type 2, which is a nozzle for use with dispensing hoses that remain fully pressurized at dispenser shutdown. A separate three-way valve connected directly, or indirectly, to the inlet of the nozzle is required to safely vent trapped gas prior to nozzle disconnection. The nozzle shall not permit the flow of gas if unconnected. Venting is required prior to disconnection of the nozzle (see 10.2).

c) Type 3, which is a nozzle for use with dispensing hoses which are automatically depressurised (0,5 MPa and below) at dispenser shutdown (see 10.2).