ISO 7778 pdf download

ISO 7778 pdf download Through-thickness characteristics for steel products

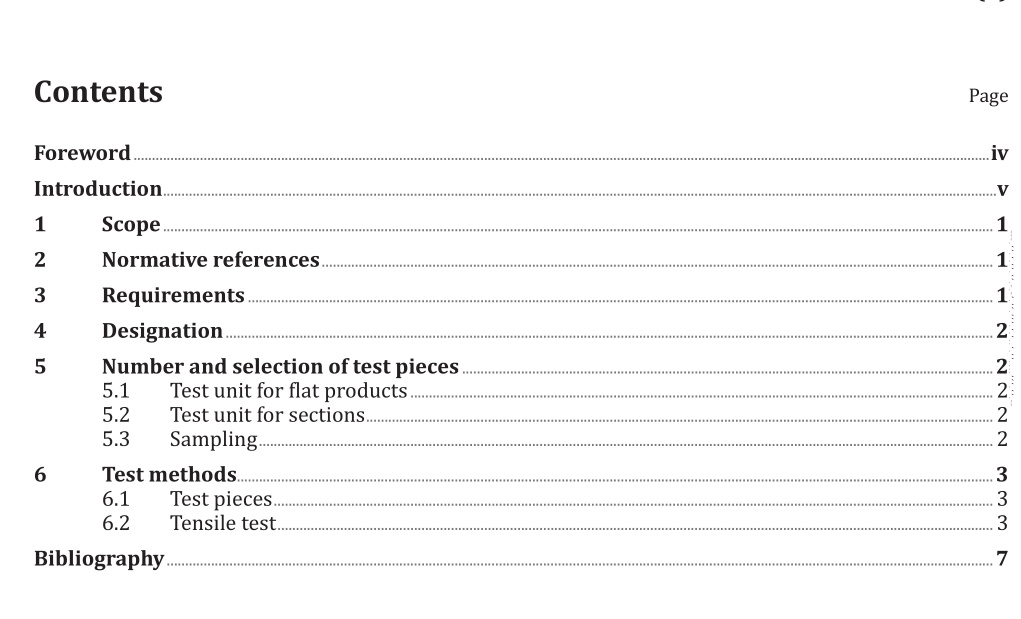

Scope

This International Standard specifies the criteria for through-thickness reduction of area propertiesspecified in the direction of thickness perpendicular to the surface. This International Standard alsospecifies the test conditions by which conformance to the specified criteria is evaluated.

This International Standard applies to fullykilled steel with a specified minimum yield strength or proofstrength <960 MPa and supplied as plates, wide flats, or sections of thickness from 15 mm to 400 mm.

The application of this International Standard to products <15 mm or >400 mm or having minimumspecified yield strengths or proof strengths >960 MPa will be the subject of agreement when ordering.

The requirements ofthis International Standard supplement other International Standards that specifythe qualities of products (plate, wide flats, and sections).

2 Normative references

The following documents,in whole or in part, are normatively referenced in this document and areindispensable for its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies

ISO 377, Steel and steel products — Location and preparation of samples and test pieces for mechanicaltesting

ISO 404, Steel and steel products — General technical delivery requirements

ISO 6892-1, Metallic materials – Tensile testing – Part 1: Method oftest at room temperature

ISO 17577:2006, Steel — Utrasonic testing for steel flat products of thickness equal to or greater than 6mm

3 Requirements

Table 1 gives the minimum average values and the minimum individual values for the reduction of areawhich the products shall satisfy according to their class.

4 Designation The qualities of steel with specified through-thickness properties shall be marked by adding a plus sign and the class number after the designation of the steel. EXAMPLE S355D+Z35.

5 Number and selection of test pieces

5.1 Test unit for flat products See Table 2.

— for sulfur >0,005 %: testing shall be per rolled unit (R) in the same heat treatment condition (parent plate or wide flat);

— for sulfur ≤0,005 %: at the option of the manufacturer, the test unit shall be type 1 or type 2.

— Type 1 testing: per test unit consisting of products from the same heat (H) which have undergone the same heat treatment and have nominal thicknesses which do not differ by more than 20 % compared with the minimum thickness of the test unit. Ultrasonic testing in accordance to ISO 17577:2006, Table 4, class B2, is mandatory for all the products of the test unit.

— Type 2 testing: per test unit consisting of products from the same heat which have undergone the same heat treatment and have a total mass of ≤ 40 t (L) and have nominal thicknesses which do not differ by more than 20 % compared with the minimum thickness of the test unit.