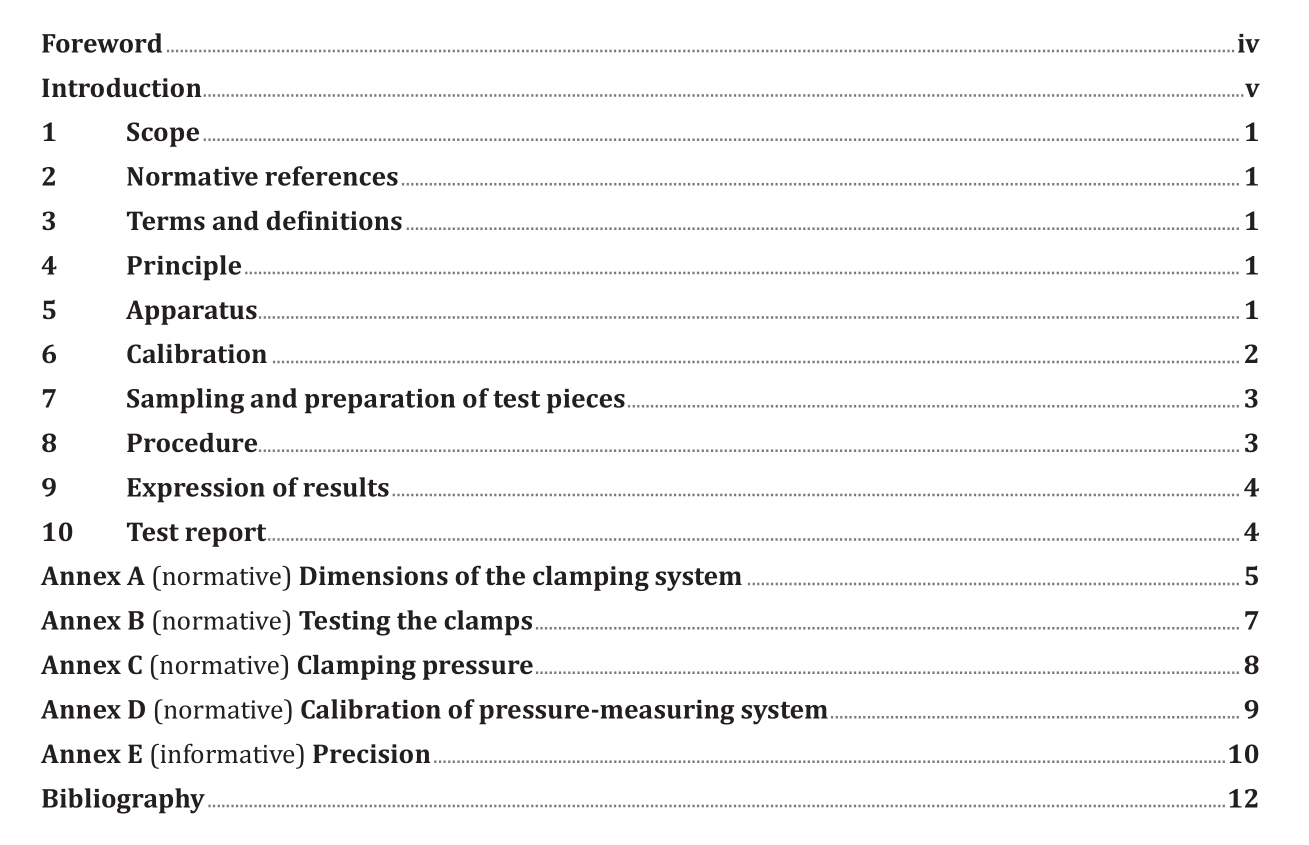

ISO 2758 pdf download

ISO 2758 pdf download Paper — Determination of bursting strength

This International Standard specifies a method for measuring the bursting strength of paper submittedto increasing hydraulic pressure. lt is applicable to paper having bursting strengths within the range70 kPa to 1 400 kPa, lt is not intended to be used for the components (such as fluting medium orlinerboard) ofa combined board, for which the method given in ISO 275911] is more suitable.

In the absence of any commercial agreement as to which method should be used for testing the materialmaterials with bursting strengths below 600 kPa should be tested according to this InternationalStandard.

Normative references

The following documents,in whole or in part, are normatively referenced in this document and areindispensable for its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies.

ISO 186, Paper and board – Sampling to determine average quality

ISO 187, Paper, board and pulps — Standard atmosphere for conditioning and testing and procedure formonitoring the atmosphere and conditioning ofsamplesISO 536, Paper and board – Determination ofgrammage

3 Terms and definitions

For the purposes ofthis document, the following terms and definitions apply.31bursting strength

maximum pressure developed bythe hydraulic system in forcing an elastic diaphragm through a circulararea of the paper when the pressure is applied in the manner described in the method

Note 1 to entry: The indicated bursting pressure includes the pressure required to extend the diaphragm duringthe test.

3.2

burstindex

bursting strength of paper, in kilopascals, divided by the grammage of the paper determined inaccordance with ISO 536

4 Principle

A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free tobulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm untithe test piece ruptures. The bursting strength of the test piece is the maximum value of the appliedhydraulic pressure.

Apparatus

The apparatus shall contain, as a minimum, the features described in 5.1 to 5.4.

5.1 Clamping system, for clamping the test piece firmly and uniformly between two annular, plane, parallel surfaces which shall be smooth (but not polished) and grooved as described in Annex A, which also gives the dimensions of the clamping system.

One clamping plate shall be held in a swivel joint or similar device so as to ensure that the clamping pressure is distributed evenly.

Under the load used for testing, the circular openings in the two clamping faces shall be concentric to within 0,25 mm and the clamping surfaces shall be flat and parallel. The method of checking the clamps is given in Annex B.