ISO 11426 pdf download

ISO 11426 pdf download Jewellery — Determination of gold in gold jewellery alloys — Cupellation method (fire assay)

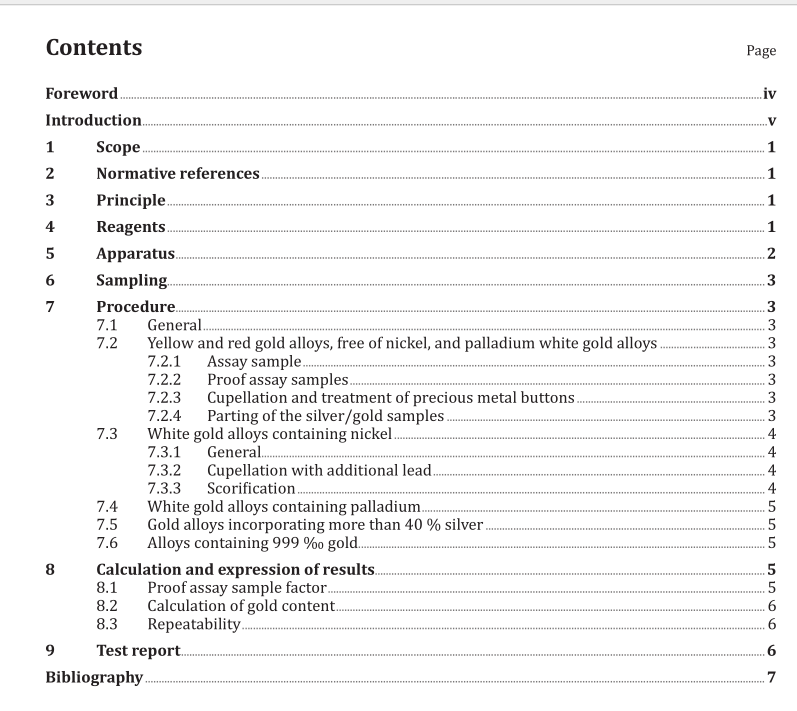

Scope

This International Standard specifies a cupellation method (fire assay) for the determination of gold ingold jewellery alloys. The gold content of the alloys should preferably lie between 333 and 999 parts perthousand (%o).

The procedure is applicable specifically to gold alloys incorporating silver, copper, and zinc. Somemodifications are indicated where nickel and/or palladium are present in the so-called white gold alloys,as well as for alloys containing 990 or more parts per thousand (%o) of gold.

This International Standard is intended to be used as the recommended method for the determinationoffineness in alloys covered by ISO 9202.

2 Normative references

The following documents,in whole or in part, are normatively referenced in this document and areindispensable for its application. For dated references, only the edition cited applies. For undatedreferences, the latest edition of the referenced document (including any amendments) applies.

SO 11596, Jewellery – Sampling of precious metal alloys for and in jewellery and associated products

3 Principle

The gold alloys are inquarted with silver, compounded with lead, and cupelled in a cupellation furnaceuntil a precious metal button is obtained. After flattening and rolling,the silver is extracted (parted) innitric acid and the gold weighed.Possible systematic errors in the procedure are eliminated by assaying

standard proof samples in parallel.NOTEInquartation is the addition of silver to gold alloys in a specific ratio in order to enable the parting ofgold from silver by means of nitric acid.

4 Reagents

During the analysis, unless otherwise stated, use only reagents of recognized analytical grade and onlydistilled water or water of equivalent purity.

4.1 Nitric acid (HNO3), 33 %(mass fraction), with sufficientlylow content ofhalides (check with silvernitrate test).

4.2Nitric acid (HNO), 49 % (mass fraction), with sufficiently low content ofhalides (check with silvernitrate test).

4.3 Lead, assay grade, free of precious metals and bismuth, as foil, beads, or tablets.

4.4 Pure silver, for inquartation, minimum purity 999 parts per thousand (%o) by mass, free of goldand platinum group metals.

5 Apparatus

5.1 Ordinary laboratory apparatus.

5.2 Cupellation furnace, in which an oxidizing atmosphere can be maintained.

CAUTION — A standard muffle furnace is not satisfactory for this purpose.

5.3 Magnesia cupels, in form of single or block cupels, capable of absorbing the resulting lead and base metal oxides.

5.4 Parting flasks or nitric acid resistant basket, with thimbles.

5.5 Annealing crucibles, made of refractory materials.

5.6 Cupellation tongs.

5.7 Assay pliers.

5.8 Polished anvil, which may be replaced by a press, polished and reserved for this purpose.

5.9 Polished hammer, of minimum mass 400 g, which may be replaced by a press, polished, and reserved for this purpose.

5.10 Scorification dishes, usually of 50 mm in diameter.

5.11 Jewellers’ rolls.

5.12 Scorification tongs.

5.13 Assay cleaning brush.

5.14 Analytical balance, with a reading accuracy of 0,01 mg.