IEC 60317-51 pdf download

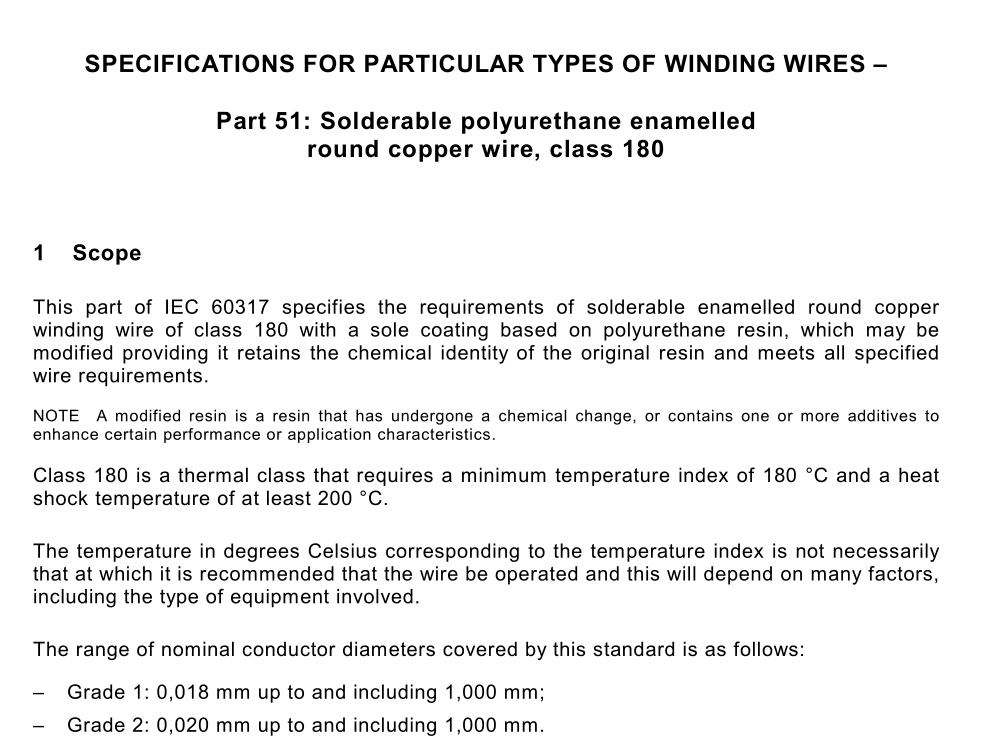

IEC 60317-51 pdf download Specifications for particular types of winding wires — Part 51: Solderable polyurethane enamelled round copper wire, class 180

1 scope

This part of lEC 60317 specifies the requirements of solderable enamelled round copperwinding wire of class 180 with a sole coating based on polyurethane resin,which may bemodified providing it retains the chemical identity of the original resin and meets all specifiedwire requirements.

NOTE A modified resin is a resin that has undergone a chemical change,or contains one or more additives toenhance certain performance or application characteristics.

Class 180 is a thermal class that requires a minimum temperature index of 180 °C and a heatshock temperature of at least 200 °c.

The temperature in degrees Celsius corresponding to the temperature index is not necessarilythat at which it is recommended that the wire be operated and this will depend on many factors,including the type of equipment involved.

The range of nominal conductor diameters covered by this standard is as follows:

– Grade 1: 0,018 mm up to and including 1,000 mm;

-Grade 2: 0,020 mm up to and including 1,000 mm.

The nominal conductor diameters are specified in clause 4 of lEC 60317-O-1.

2Normative references

The following normative documents contain provisions which,through reference in this text,constitute provisions of this part of lEC 60317.For dated references, subsequent amendmentsto,or revisions of,any of these publications do not apply. However,parties to agreementsbased on this part of lEc 60317 are encouraged to investigate the possibility of applying themost recent editions of the normative documents indicated below.For undated references, thelatest edition of the normative document referred to applies.Members of lEC and lS0 maintainregisters of currently valid International Standards.

IEC 60317-0-1:1997,Specifications for particular types of winding wires – Part 0: Generalrequirements – Section 1: Enamelled round copper wire

3Definitions and general notes on methods of test

For definitions and general notes on methods of test, see clause 3 of lEC 60317-O-1. In case ofinconsistencies between lEC 60317-0-1 and this standard,IEC 60317-51 shall prevail.

4 Dimensions

See clause 4 of IEC 6031 7-0-1 .

5 Electrical resistance

See clause 5 of IEC 6031 7-0-1 .

6 Elongation

See clause 6 of IEC 6031 7-0-1 .

7 Springiness

See clause 7 of IEC 6031 7-0-1 .

8 Flexibility and adherence

See clause 8 of IEC 6031 7-0-1 .

9 Heat shock

See clause 9 of IEC 6031 7-0-1 , where the minimum heat shock temperature shall be 200 °C.

10 Cut-through

No failure shall occur within 2 min at 230 °C.

11 Resistance to abrasion (nominal conductor diameters from 0,250 mm up to and including 1 ,000 mm)

The wire shall meet the requirements given in table 1 .