BS ISO 15995 pdf download

BS ISO 15995 pdf download Gas cylinders — Specifications and testing of LPG cylinder valves — Manually operated

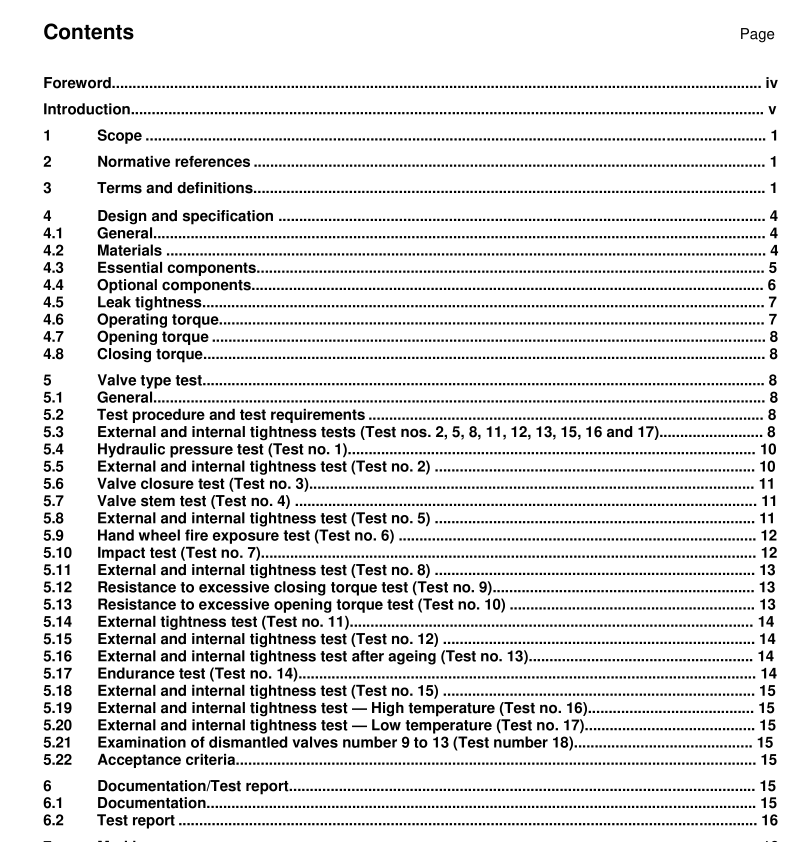

Design and specification

4.1General

4.1.1The valve shall be capable of withstanding:

operating pressures and test pressures;

mechanical stresses, including dynamic loads such as pressure shocks or cyclic changes;operating temperatures.

NOTEPressures are gauged unless otherwise specified.

4.1.2There shall be valve external and internal leak tightness for the full range of pressure and temperatureconditions.

4.1.3 The specific requirements relating to the functions, mechanical strength, pressure, operatingtemperatures, external and internal leak tightness of the valve and its components, are detailed in thefollowing subclauses of this clause and/or in the relevant test of Clause 5.

4.2 Materials

4.2.1General

Materials in contact with LPG shall be physically and chemically compatible with LPG under all operatingconditions for which the valve is designed (see ISO 11114-1 and ISO 11114-2).

in selecting an appropriate material for valve components, it is important to select not only for adequatestrength in service, but also to give consideration to other modes of failure due to atmospheric corosionbrass dezincification, stress corrosion, shock loads, and material failure.

4.2.2Operating temperatures

Materials used shall be suitable for the temperatures for which the valve is designed.

The minimum operating temperature to which the valve is expected to be exposed during normal use is minus20 °C. In service temperatures below this may be encountered during short periods, for example, during filingWhere necessary, e.g. in some countries and for certain applications, lower minimum operating temperaturesshall be used. When equipment is designed for a temperature of minus 40 °C, it shall also meet therequirements of Annex D.

The maximum operating temperature to which the valve is expected to be exposed during normal operation is65°C. In service, this temperature may be exceeded for short periods.

4.2.3Copper alloys

Valve bodies made from copper alloys shall be manufactured from materials in accordance with recognizedstandards, e.g. EN 12164 and EN 12165, or from alloys of equivalent properties and standards.

4.24 Non-metallic materials

Non-metallic materials in contact with LPG shall be compatible with LPG, e.g. ISO 11114-2. They shall notdistort, harden or adhere to the body or seat face to such an extent as to impair the function of the valve.