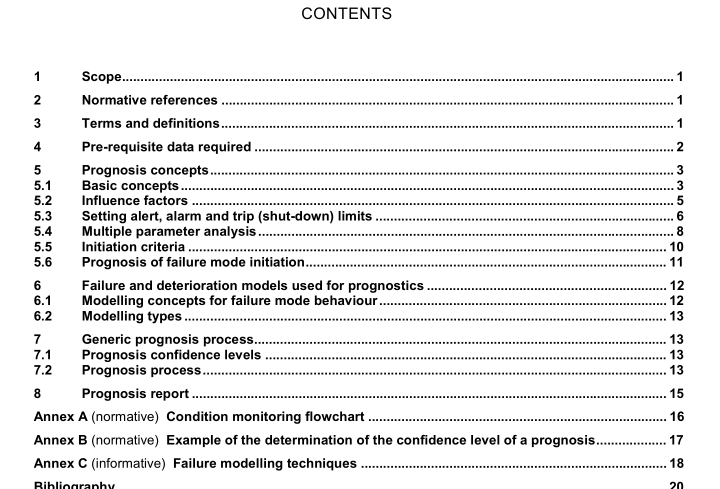

AS ISO 13381.1 pdf download

AS ISO 13381.1 pdf download Condition monitoring and diagnostics of machines—Prognostics Part 1: General guidelines

1 Scope

This International Standard provides guidance for the development of prognosis processes. It is intended to allow the users and manufacturers of condition monitoring and diagnostics systems to share common concepts in the fields of machinery fault prognosis,

to enable users to determine the necessary data, characteristics and behaviour necessary for accurate prognosis,

to outline an appropriate approach to prognosis development, and

to introduce prognoses concepts in order to facilitate the development of future systems and training.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 13372, Condition monitoring and diagnostics of machines — Vocabulary

ISO 17359, Condition monitoring and diagnostics of machines — General guidelines

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13372 and the following apply.

3.1

prognosis

estimation of time to failure and risk for one or more existing and future failure modes

3.2

confidence level

figure of merit that indicates the degree of certainty that the diagnosis/prognosis is correct

NOTE 1 It is expressed as a percentage.

NOTE 2This value is essentially a figure representing the cumulative effect of error sources on the final certainty orconfidence in the accuracy of the outcome. Such a figure can be determined algorithmically or via a weighted assessmentsystem.

3.3

root causeset of conditions and/or actions that occur at the beginning of a sequence of events that result in the initiationof a failure mode

3.4

failure modes effects analysis

FMEA

pre-production design and development process to help determine the ways that a machine could fail, and toassess the associated effects of such failure

NOTEThe FMEA procedure is outlined in BS 5760-5

3.5

failure modes effects criticality analysis

FMECA

process that adds an economic, financial and/or safety component to FMEA to assist in maintenancemanagement decisions

NOTEThe FMECA procedure is outlined in IEC 60812.

3.6

failure modes symptoms analysis

FMSA

process based on FMECA that documents the symptoms produced by each mode, and the most effectivedetection and monitoring techniques, in order to develop and optimize a monitoring programme

NOTEThis process is outlined in ISO 13379.

37

estimated time to failure

ETTF

estimation of the period from the current point in time to the point in time when the monitored machine isdeemed to be in the failed condition

4 Pre-requisite data required

For the general concepts for condition monitoring, see lSO 17359. These form the basis for the prognosisprocess and its pre-requisites. Prognosis requires collection of documented data covering the following: